Can 2 Profile ways Cubic Connectors accommodate different profiles and materials in a structural framework?

The ability of 2 Profile ways Cubic Connectors to accommodate different profiles and materials in a structural framework depends on the specific design and specifications of the connectors. Here are some considerations:

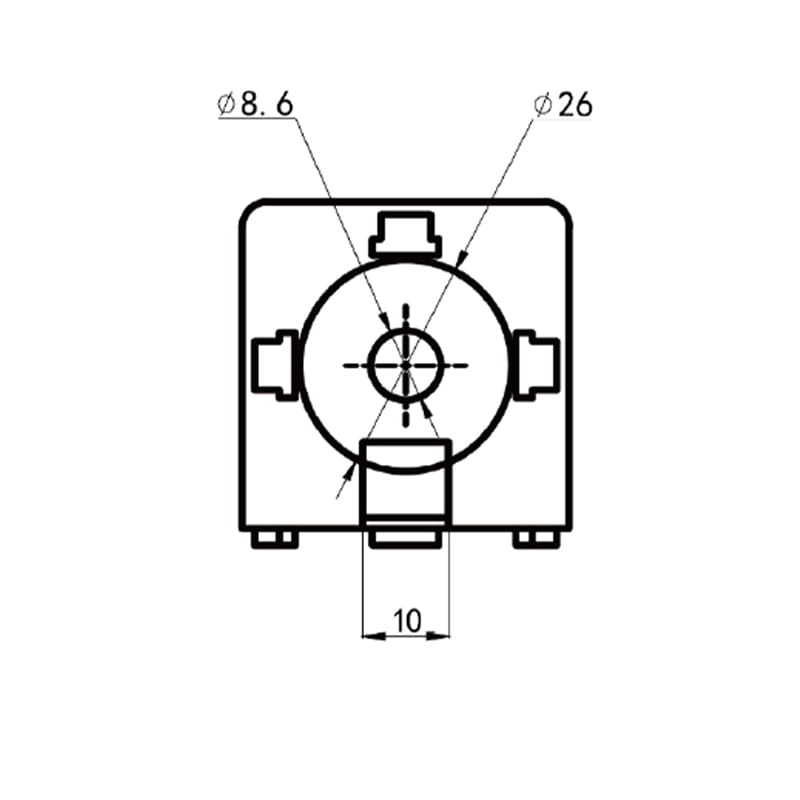

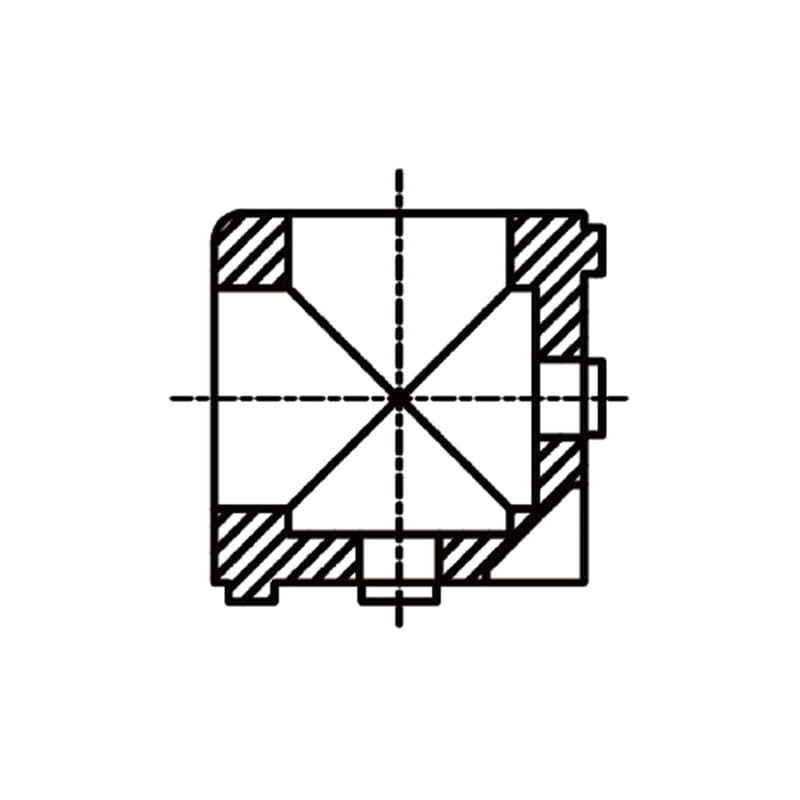

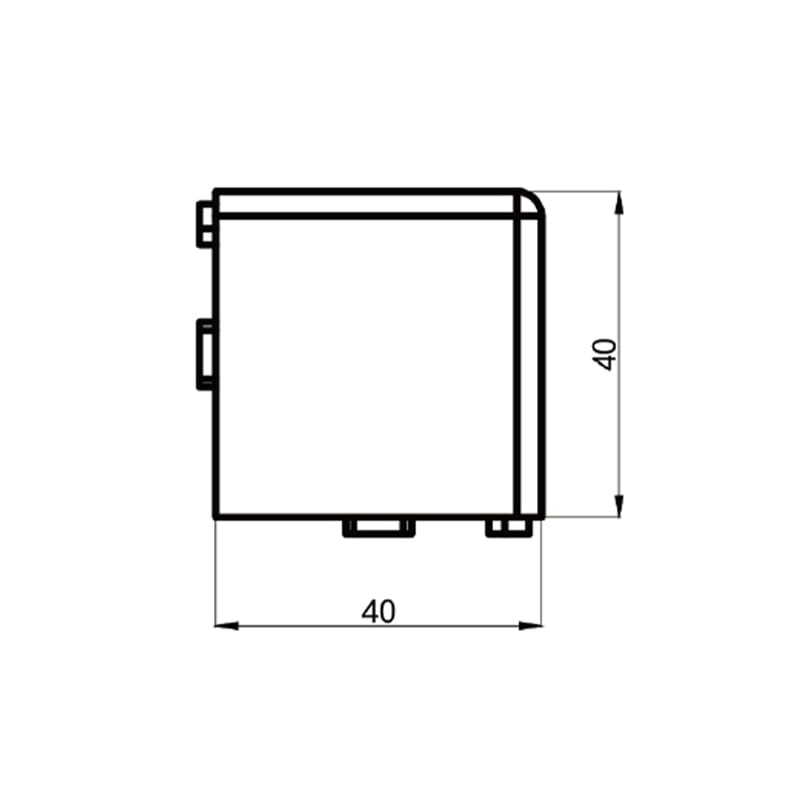

Design Flexibility: Many 2 Profile ways Cubic Connectors are designed with flexibility in mind, allowing them to accommodate a variety of profiles. The connectors may feature adjustable mechanisms or modular components that can adapt to different sizes and shapes.

Profile Compatibility: Check the specifications provided by the connector manufacturer to ensure compatibility with various profiles. This may include profiles of different cross-sectional shapes, sizes, and materials.

Material Compatibility: Some connectors are versatile enough to work with different construction materials, such as steel, aluminum, or composite materials. Ensure that the chosen connector is suitable for the specific material used in the structural profiles.

Customization Options: Certain

2 Profile ways Cubic Connectors may offer customization options, allowing users to adapt the connector to the specific requirements of their project, including the type of profiles and materials used.

Universal Connectors: Some connectors are designed as universal solutions, intended to work with a broad range of profiles and materials. These connectors often feature adjustable elements or multiple connection points to accommodate variations in profile dimensions.

Load-Bearing Considerations: When selecting connectors for a structural framework, it's essential to consider the load-bearing requirements. Ensure that the chosen connectors are suitable for the loads and forces expected in the application, regardless of the profile and material.

Manufacturer Guidelines: Follow the guidelines provided by the connector manufacturer regarding profile and material compatibility. Manufacturers typically provide information on the range of profiles and materials that their connectors can effectively accommodate.

Application-Specific Connectors: In certain cases, connectors may be designed for specific applications or industries, and their compatibility with profiles and materials may be optimized for those particular use cases.

In what types of construction or manufacturing projects are 2 Profile ways Cubic Connectors commonly used?

2 Profile ways Cubic Connectors find application in various construction and manufacturing projects where a secure and adaptable connection between two profiles is required. Here are some types of projects where these connectors are commonly used:

Framing Systems: 2 Profile ways Cubic Connectors are often employed in framing systems for structures such as buildings, houses, and industrial facilities. They facilitate the connection of beams, columns, and other framing members.

Modular Construction: These connectors are popular in modular construction projects where prefabricated components need to be assembled quickly and efficiently. They contribute to the ease of assembly and disassembly in modular structures.

Exhibit and Display Structures: In trade shows, museums, and exhibit designs,

2 Profile ways Cubic Connectors are used to create frameworks for displays and structures that can be assembled and disassembled for different events.

Furniture Manufacturing: In the production of modular and customizable furniture, 2 Profile ways Cubic Connectors enable the assembly of different components, offering flexibility in design and functionality.

Temporary Structures: For events, festivals, and temporary installations, these connectors are employed to construct structures that can be easily assembled and dismantled, providing a quick and efficient solution.

Outdoor Shelters and Canopies: The adaptability and ease of use of 2 Profile ways Cubic Connectors make them suitable for constructing outdoor shelters, canopies, and similar structures where quick assembly is essential.