At Ningbo Minde Technology, we take immense pride in our Slot Covers, which epitomize unmatched quality, adaptability, and exceptional value. Here's how we encourage clients to make us their top choice:

1. Premium Materials for Lasting Performance:

Our Slot Covers are expertly crafted from high-performance materials including PE, PVC, and TPV. These materials are chosen for their durability, resistance to environmental factors, and long-lasting performance, ensuring your investments are well-protected.

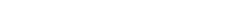

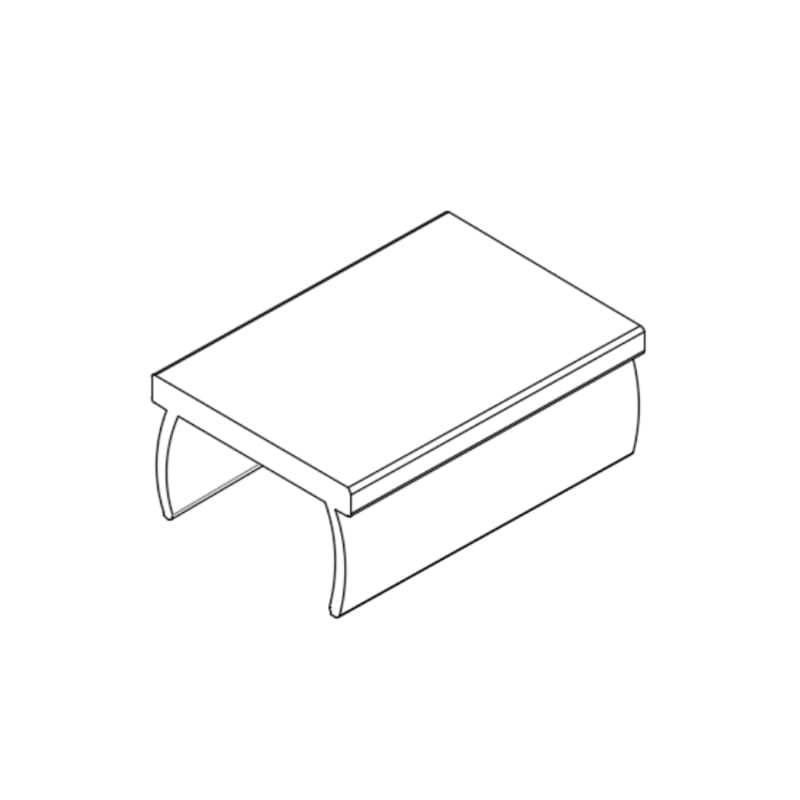

2. Customization for Precision Fit:

We understand that every project is unique. Our Slot Covers can be customized to meet your precise requirements, guaranteeing that they integrate seamlessly into your designs and provide protection.

3. Versatile Color Options:

We offer a range of color options, including black and grey, to complement different aesthetics and environments. Whether it's slot 6, slot 8, or slot 10, we have a Slot Cover that matches your specific needs.

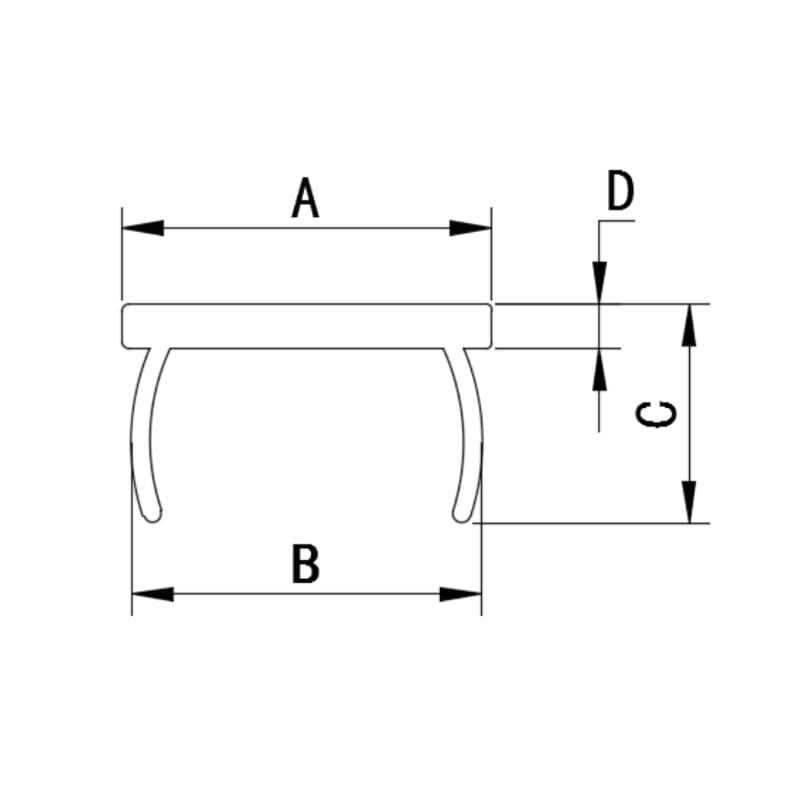

4. Comprehensive Product Range:

Our wide variety of Slot Covers caters to different profiles and applications. No matter the profile size or environmental conditions, we have a solution tailored to your exact specifications.

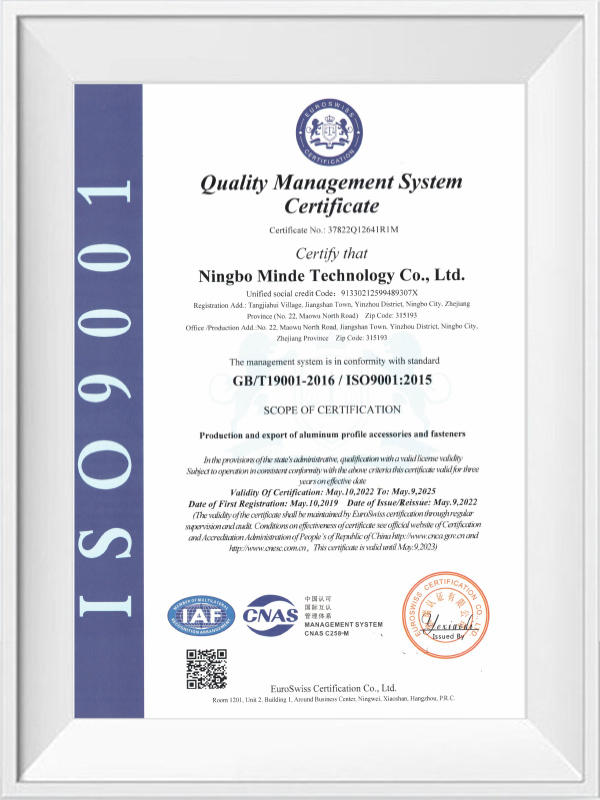

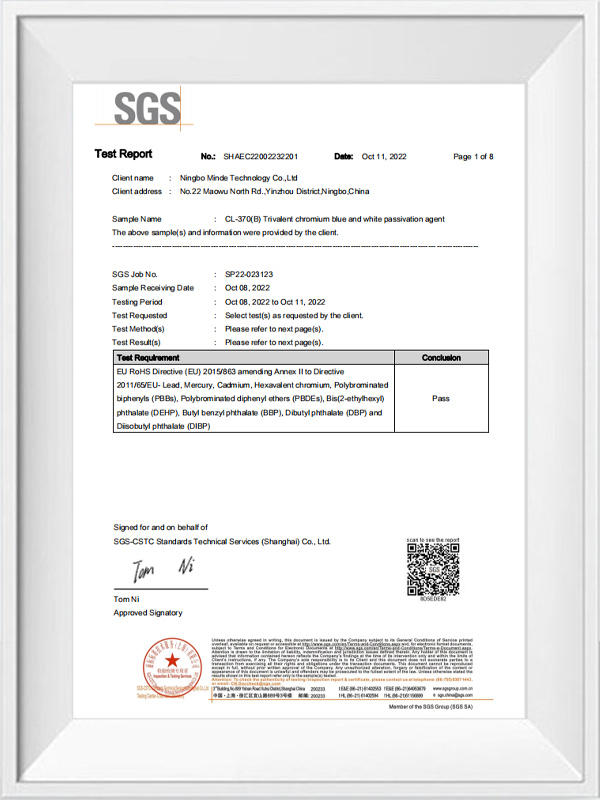

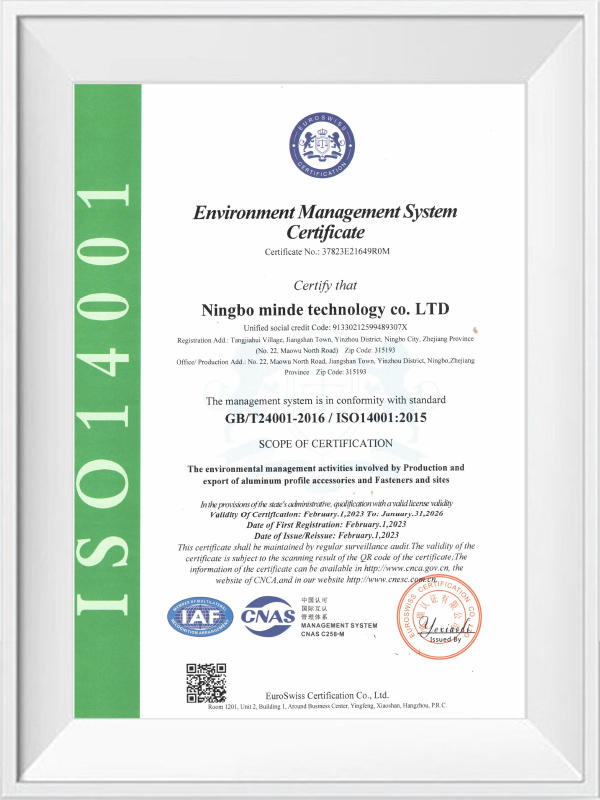

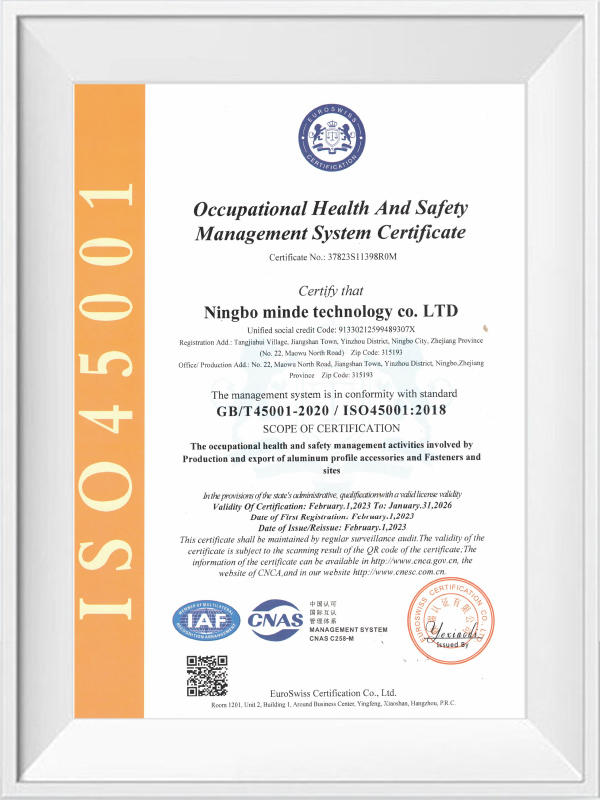

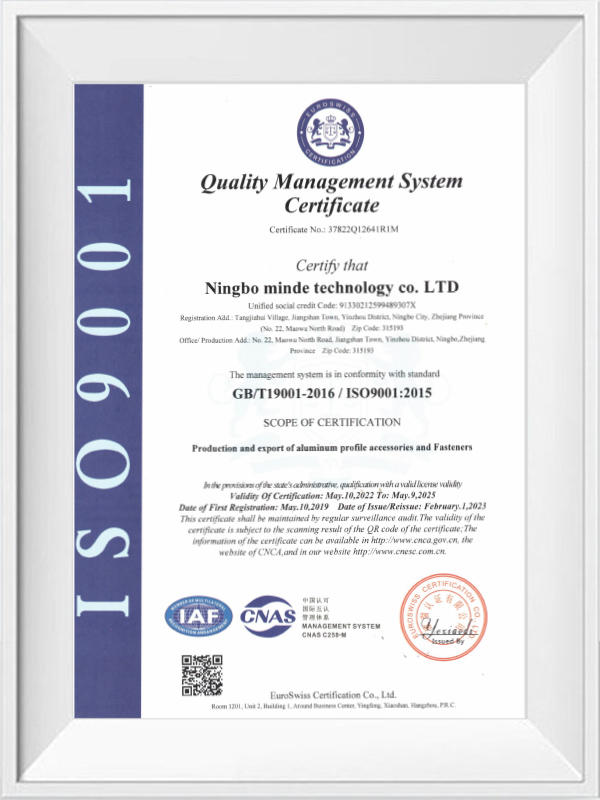

5. Rigorous Testing and Quality Assurance:

Our Slot Covers undergo rigorous testing to ensure they consistently meet and exceed your expectations. Quality control measures are our priority to guarantee reliability and performance.

6. Global Reputation and Local Expertise:

Our global reputation for excellence extends to serving clients in Europe, the United States, and worldwide. Our Slot Covers are designed to excel in diverse markets, adhering to global quality standards.

7. Customer-Centric Approach:

We approach every project with your unique requirements in mind. Our team is dedicated to understanding your needs, providing personalized solutions, and delivering the level of service and support.

8. Competitive Pricing without Compromise:

We firmly believe in offering quality without an extravagant price tag. Our Slot Covers strike the balance between quality and affordability, ensuring exceptional value for your investment.

9. Proven Track Record:

With 19 years of experience, Ningbo Minde Technology has a well-established track record of exceeding client expectations. Our history of success underscores our unwavering commitment to excellence.

10. Elevate Your Projects with Minde Technology:

By choosing Slot Covers from Ningbo Minde Technology, you elevate the protection, reliability, and performance of your projects. Our solutions ensure that your investments are safeguarded for the long term.

In conclusion, we persuade clients to choose our Slot Covers by emphasizing our unwavering commitment to quality, customization options, comprehensive product range, rigorous testing, global reputation, customer-centric approach, competitive pricing, proven track record, and the ability to enhance the success of their projects. Our Slot Covers, made from high-performance materials and available in various colors and sizes, offer durability and performance that set them apart.