How do steel angle connectors contribute to the overall stability and rigidity of a framework or assembly?

Steel angle connectors play a crucial role in contributing to the overall stability and rigidity of a framework or assembly. Their design and placement help to reinforce joints, provide structural support, and enhance the structural integrity of the entire system. Here's how steel angle connectors contribute to stability and rigidity:

Joint Reinforcement:Steel angle connectors are often used to reinforce joints in structural elements. By connecting two or more members at their meeting points, angle connectors distribute loads more evenly, reducing stress on individual joints.

Prevention of Sway and Movement:Steel angle connectors resist movement and sway by providing additional support at critical junctions. This is particularly important in structures where stability is paramount, such as buildings and bridges.

Load Distribution:The use of steel angle connectors allows for efficient distribution of loads across different structural components. This helps prevent localized stress concentrations and ensures that the entire framework shares the applied loads.

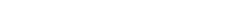

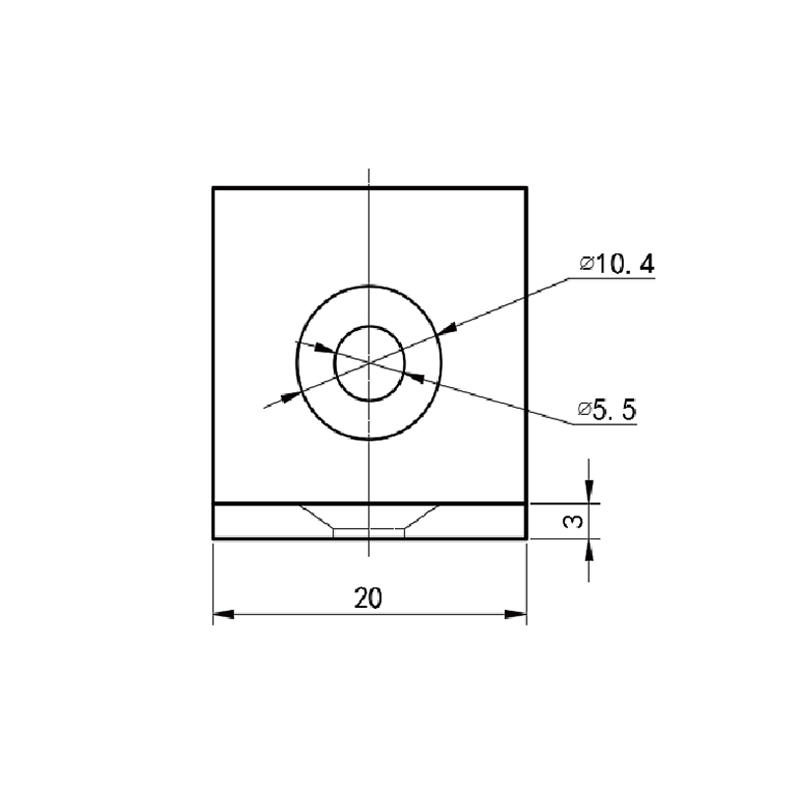

Enhanced Torsional Stability:The L-shape of

steel angle connectors contributes to enhanced torsional stability, resisting twisting forces that may be applied to the framework. This is crucial in maintaining the overall rigidity of the structure.

Reinforcement of Corners:Steel angle connectors are commonly used at corners of structures to reinforce and stabilize these critical points. This is especially important in load-bearing constructions where corners can experience higher stress.

Increased Lateral Stability:Steel angle connectors provide lateral stability to structures, preventing them from buckling or collapsing under lateral loads. This is significant in resisting forces like wind or seismic activity.

Structural Redundancy:By adding redundancy to the structure, steel angle connectors increase its overall resilience. In case of a failure or unexpected load, the presence of multiple interconnected elements can help prevent catastrophic collapse.

Resistance to Shear Forces:Steel angle connectors resist shear forces that act parallel to the surface, helping to maintain the structural integrity of the connected members and preventing sliding or displacement.

Contribution to Framing Systems:In framing systems, steel angle connectors play a vital role in connecting beams and columns, creating a rigid and stable framework. This is essential in ensuring the overall stability of the structure.

Compatibility with Other Materials:Steel angle connectors can be designed to work seamlessly with other construction materials, offering compatibility and ensuring a cohesive and stable assembly.

Steel angle connectors enhance the stability and rigidity of frameworks and assemblies by reinforcing joints, distributing loads, resisting movement, and providing additional support at critical points. Their strategic placement and design contribute significantly to the overall structural strength and stability of a construction project.