1. How does Profile T Slide Nut / T-Slot Nut work?

The

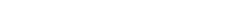

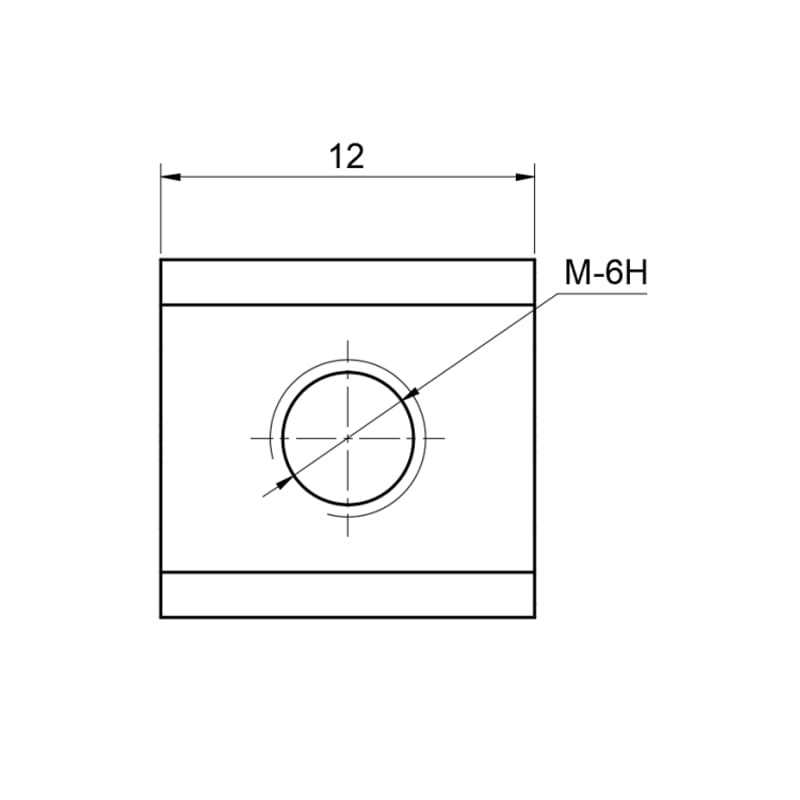

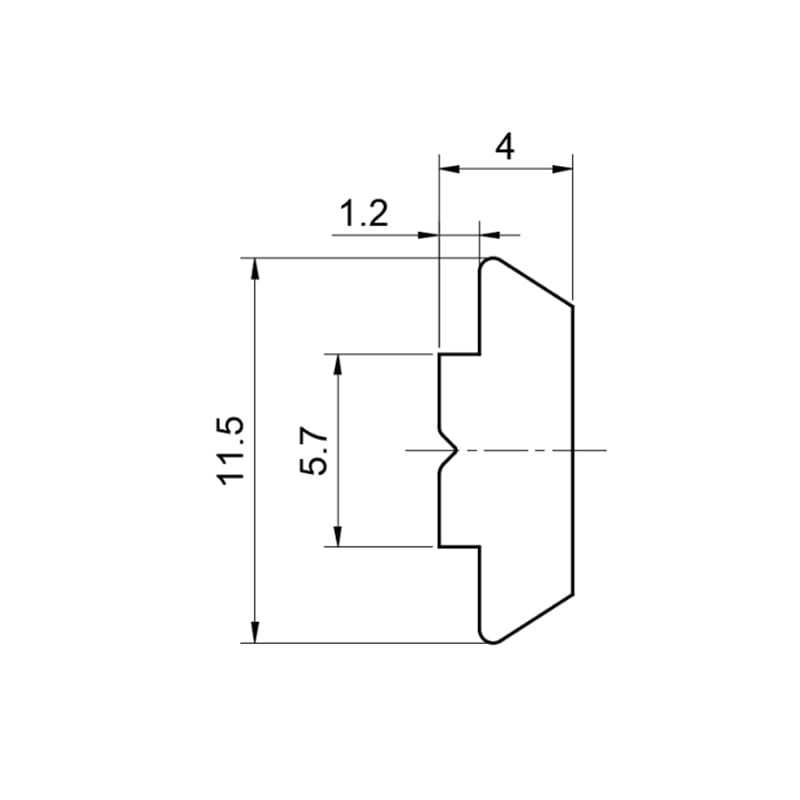

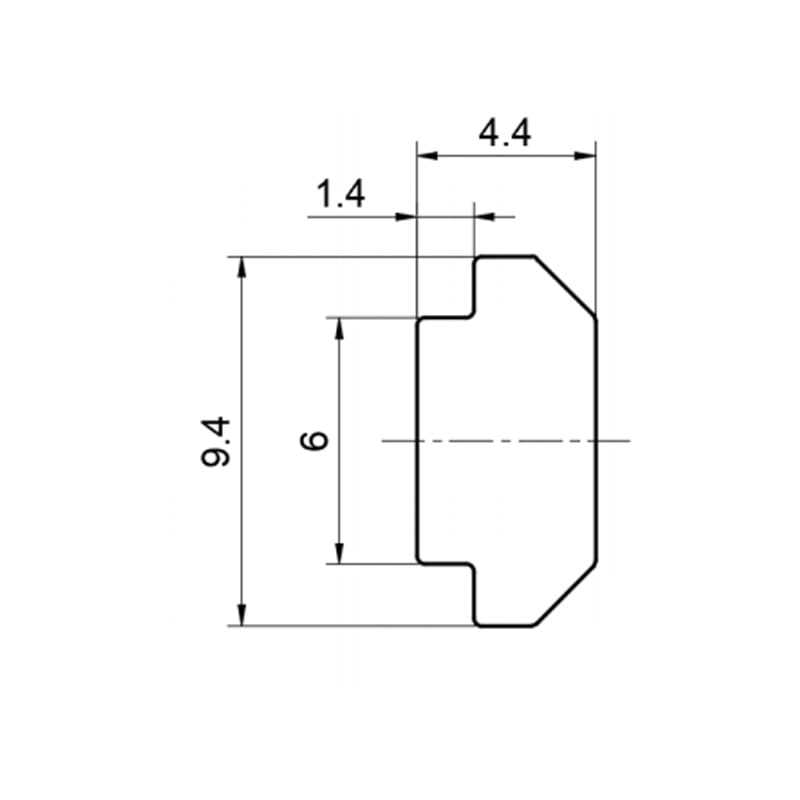

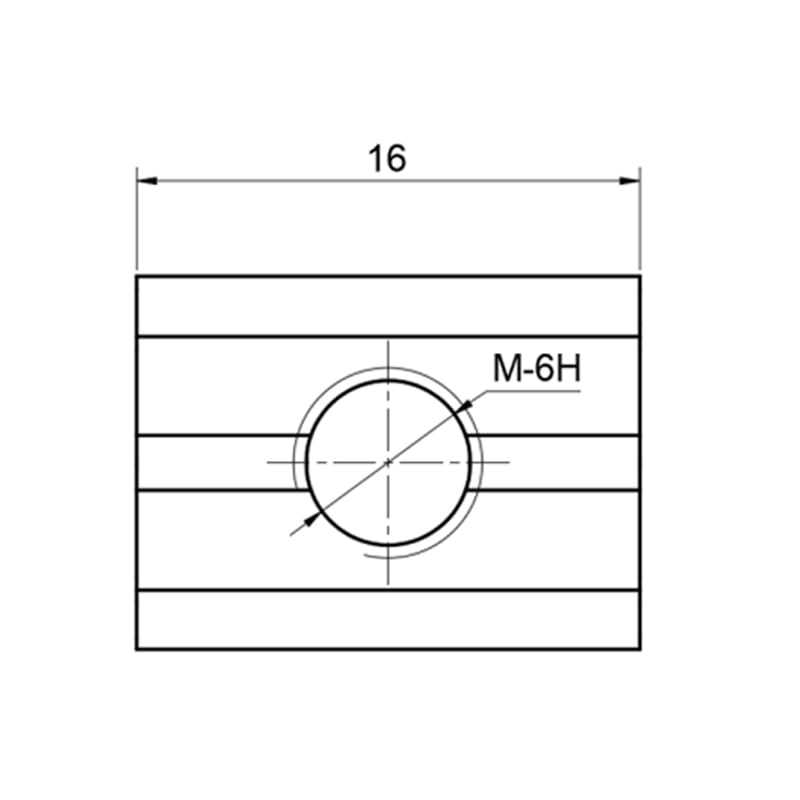

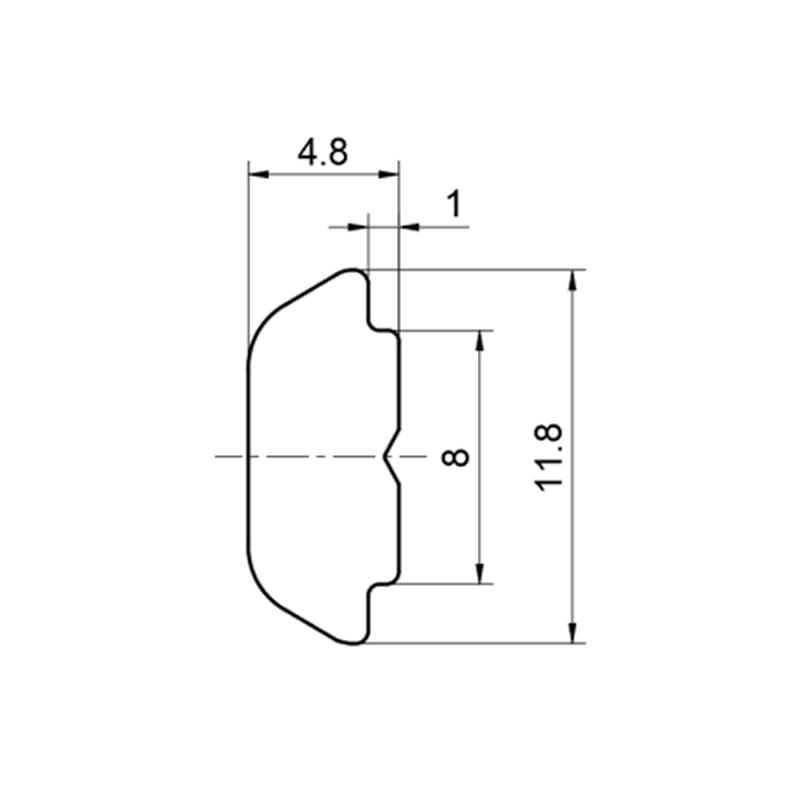

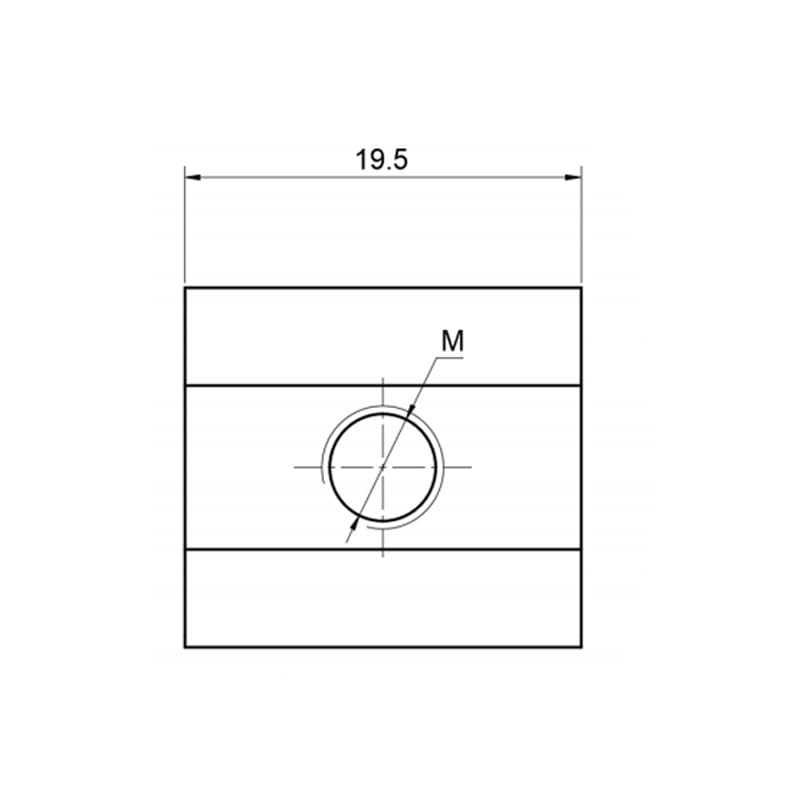

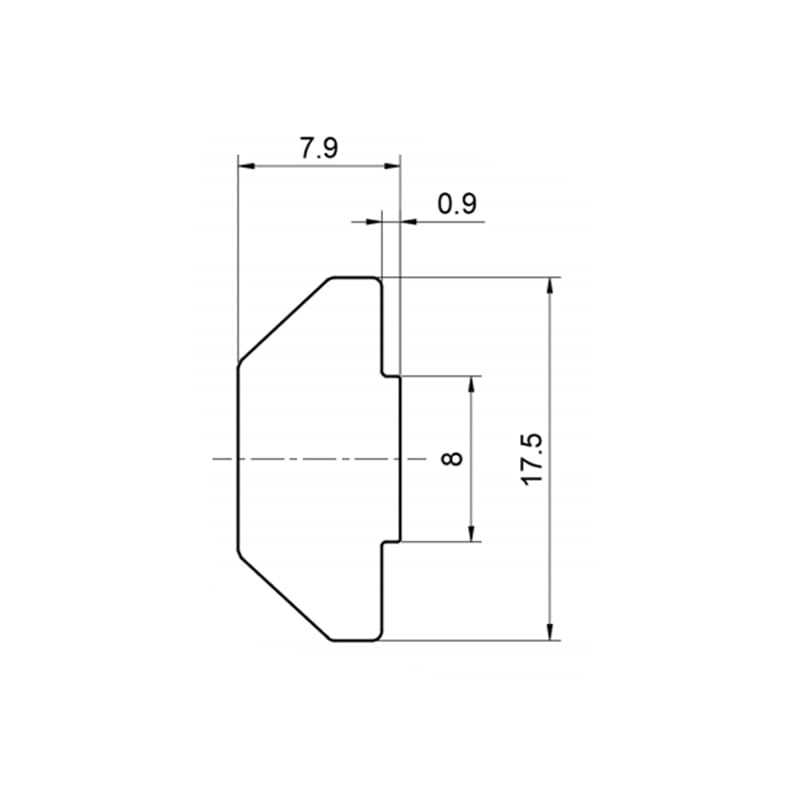

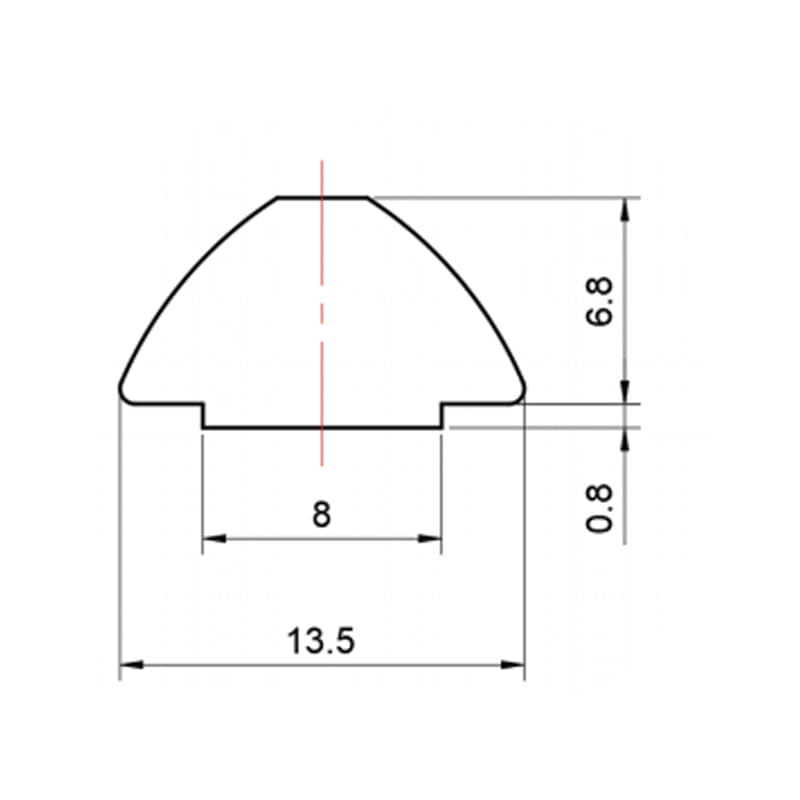

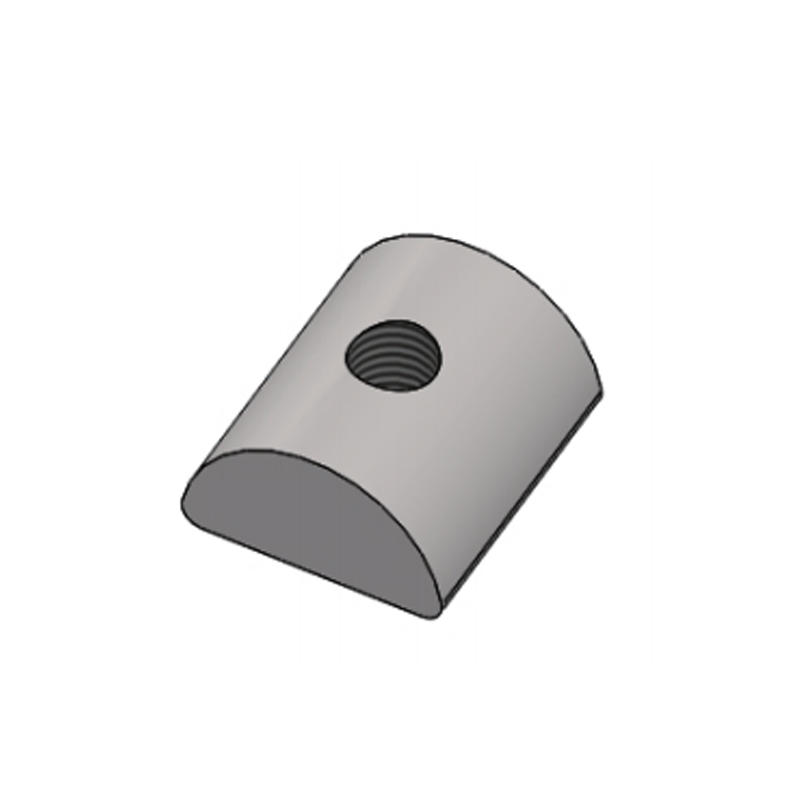

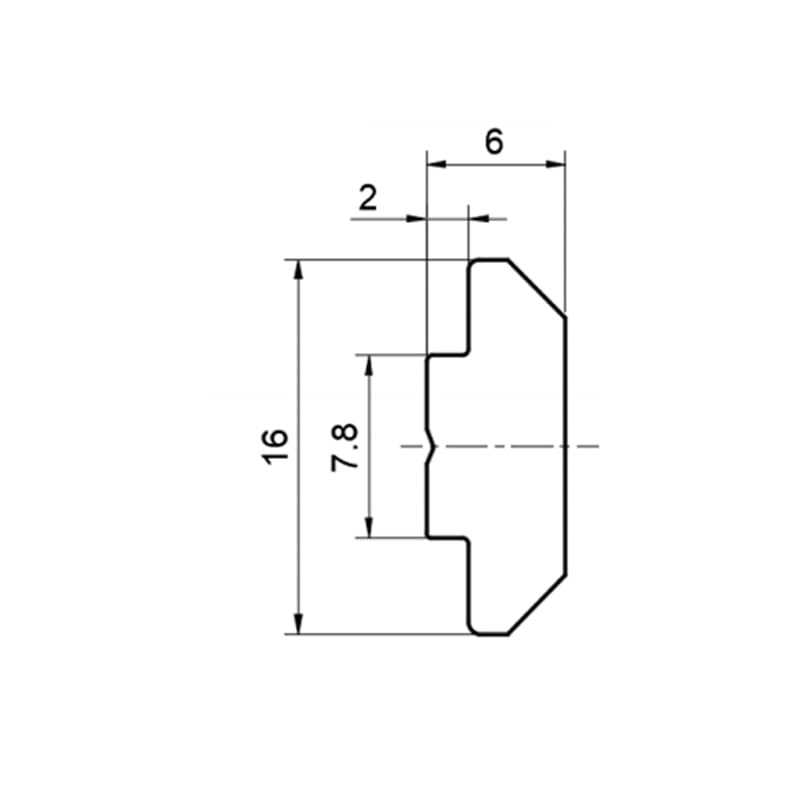

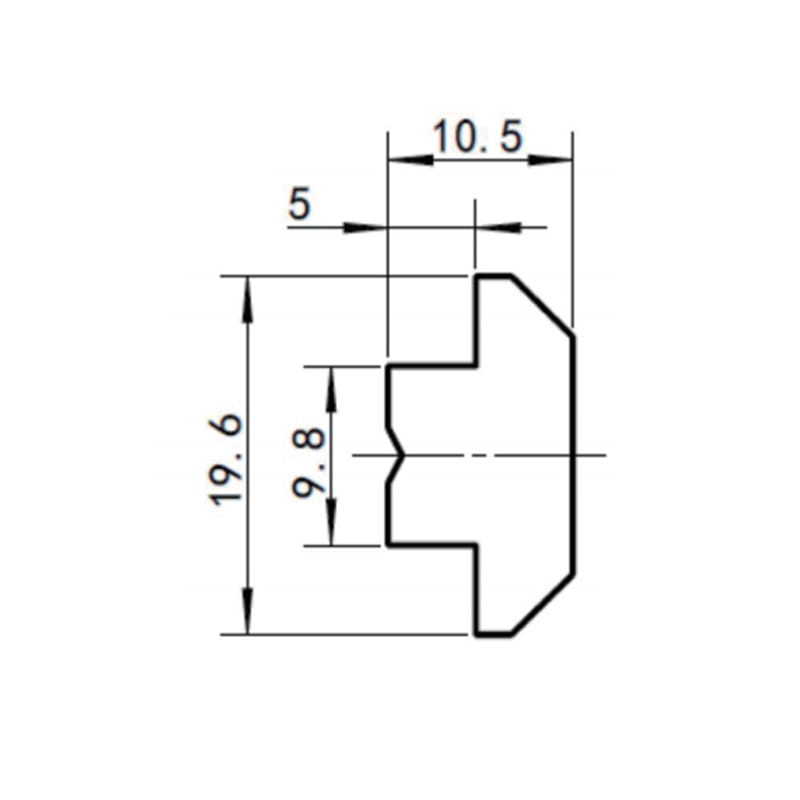

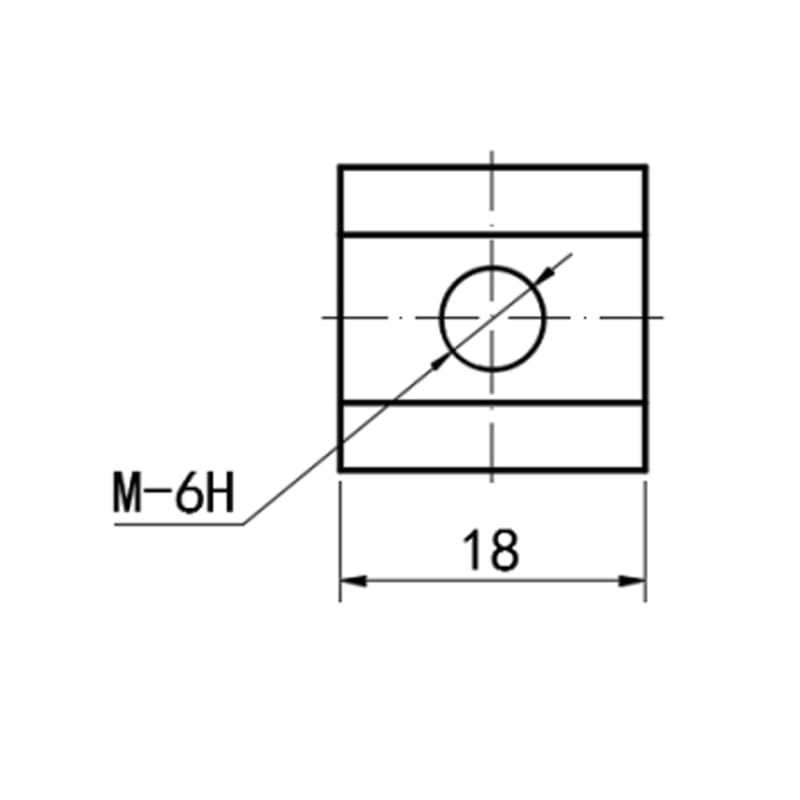

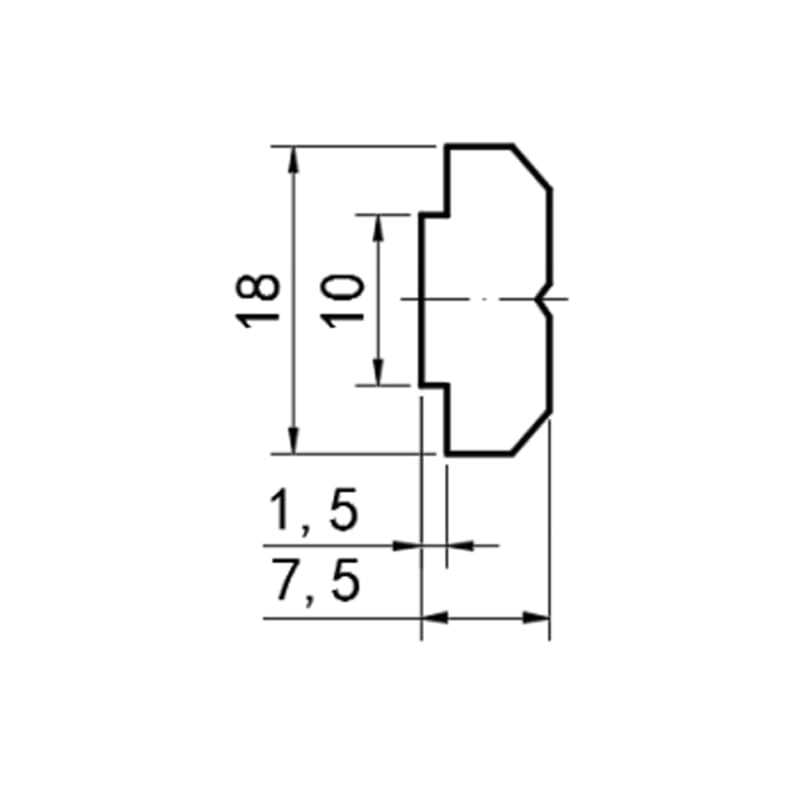

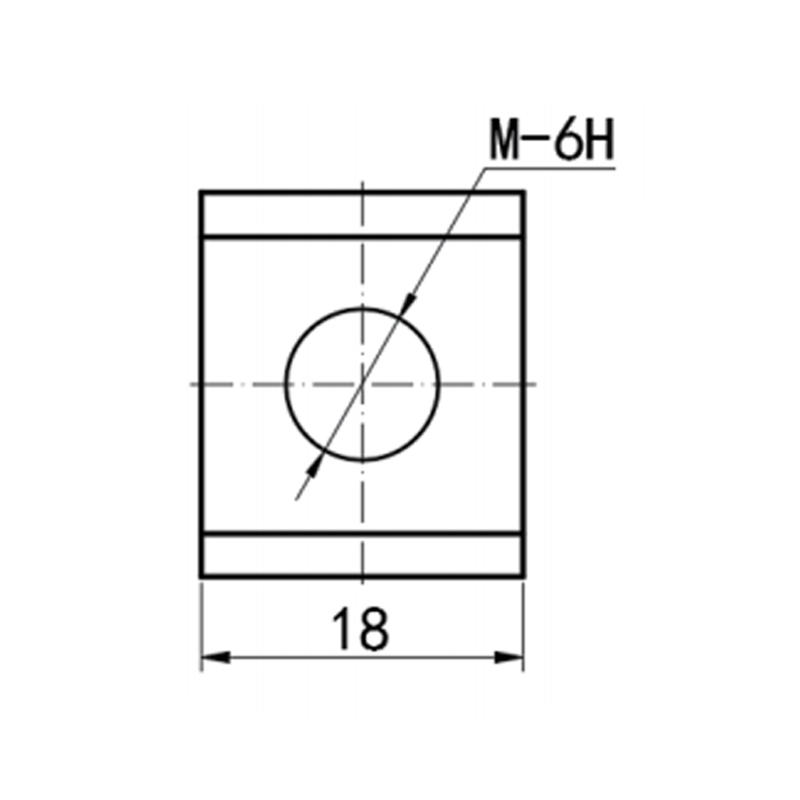

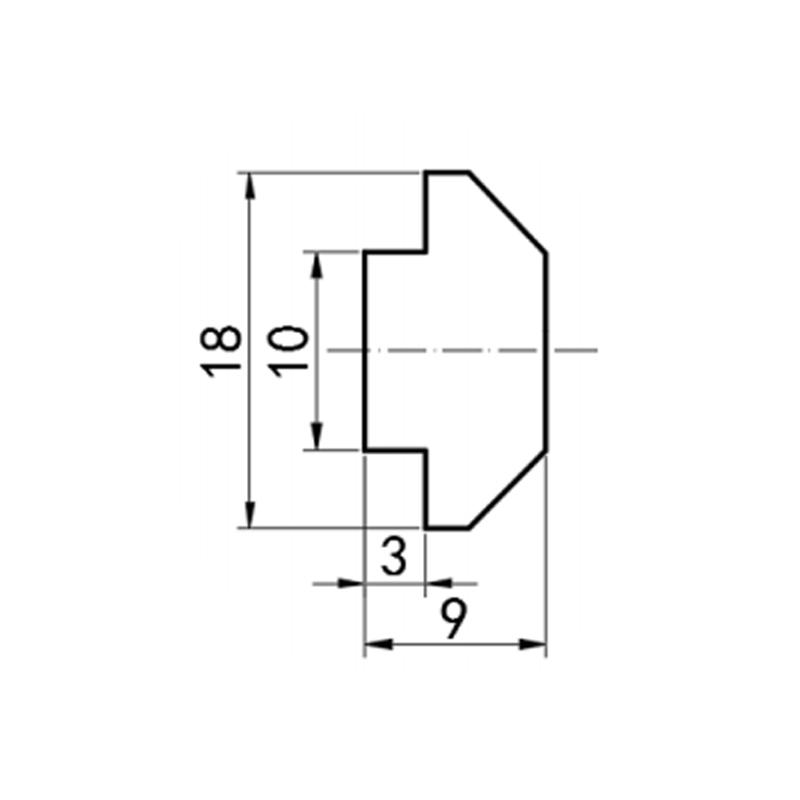

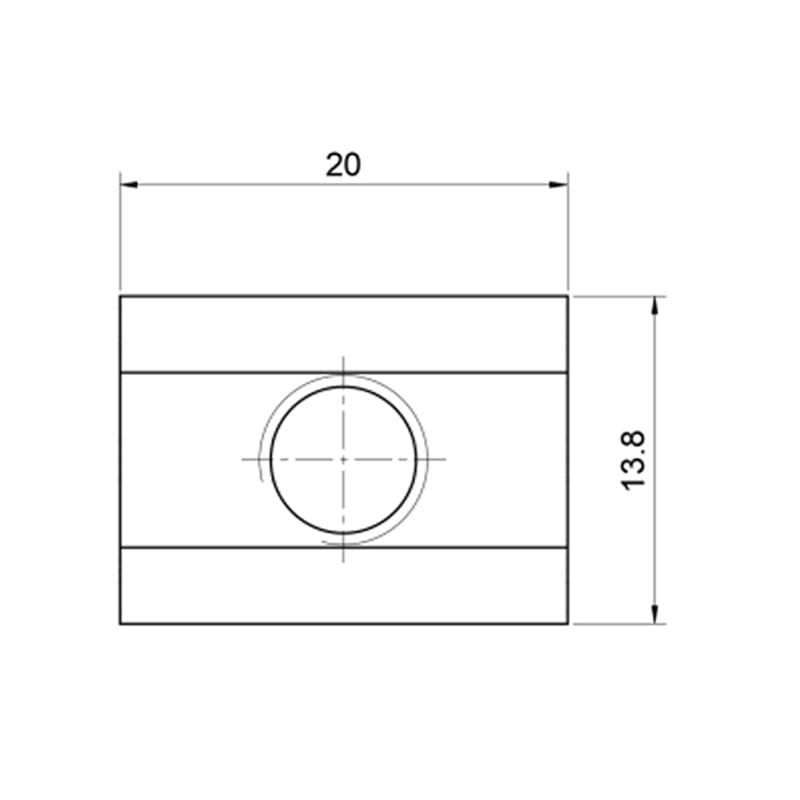

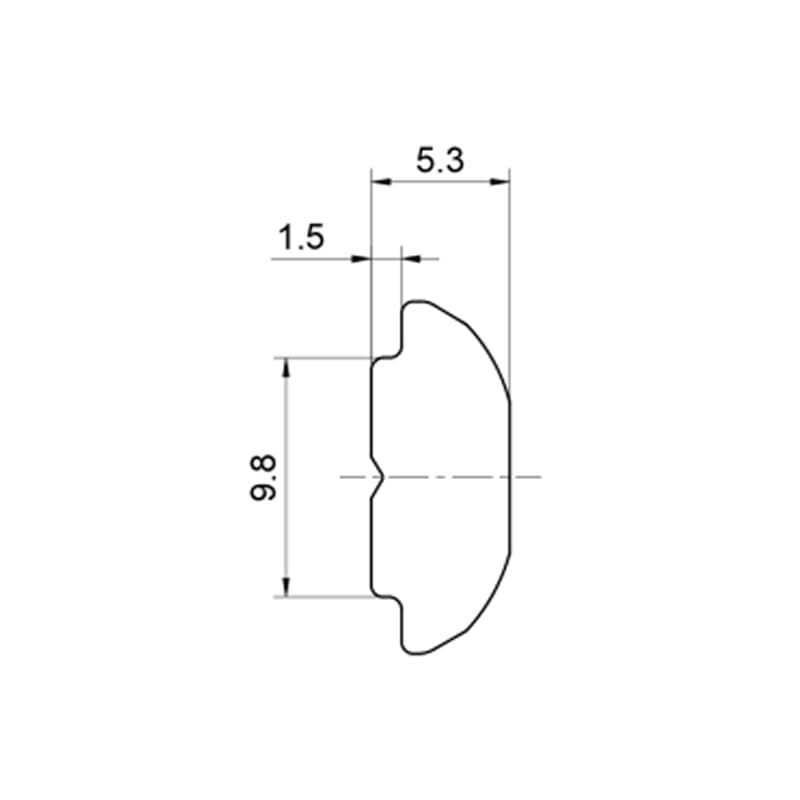

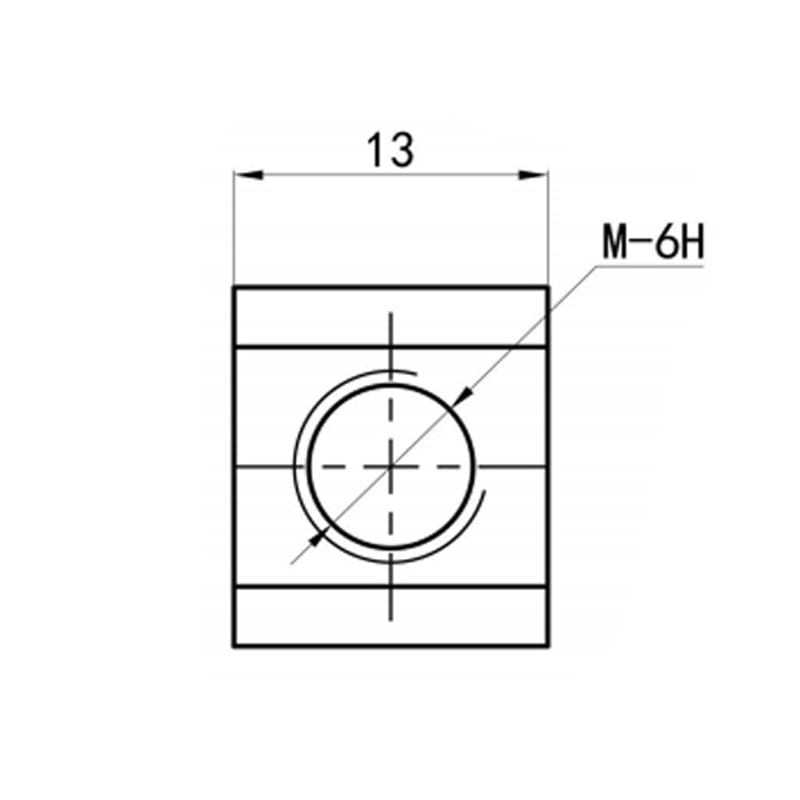

profile T slide nut / T-slot nut is an ingeniously designed connection element whose working principle is based on its fit into the T-slot structure. These nuts are designed to slide easily into the T-slots and hold in place, providing a secure connection. Its working principle is mainly based on its unique shape and design.

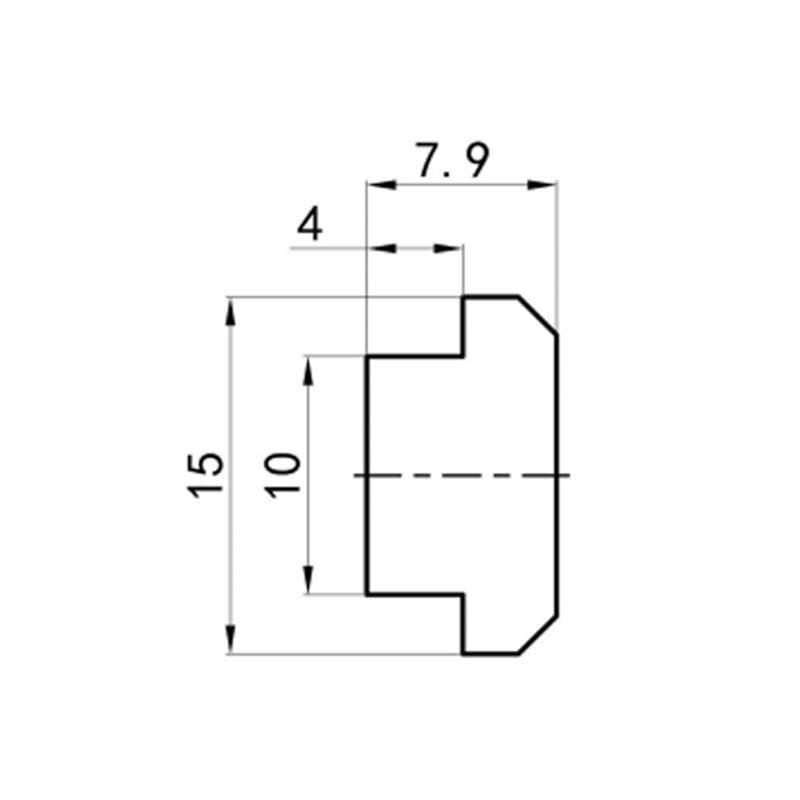

Generally, a T-slot is a special channel with a T-shaped cross-section, which is usually used for the connection and fixation of various mechanical structures and components. The Profile T Slide Nut / T-Slot Nut is designed to allow free movement in the T-slot and then rotates to secure it in the desired position.

These nuts usually have raised portions that match the size of the notch of the T-slot, ensuring a secure fit. Once in place, they are able to withstand forces in all directions, providing a reliable connection. Furthermore, their design includes some self-locking features that prevent them from loosening under vibration or load, ensuring the stability of the connection.

2. What are the characteristics of the materials and manufacturing process of Profile T Slide Nut / T-Slot Nut?

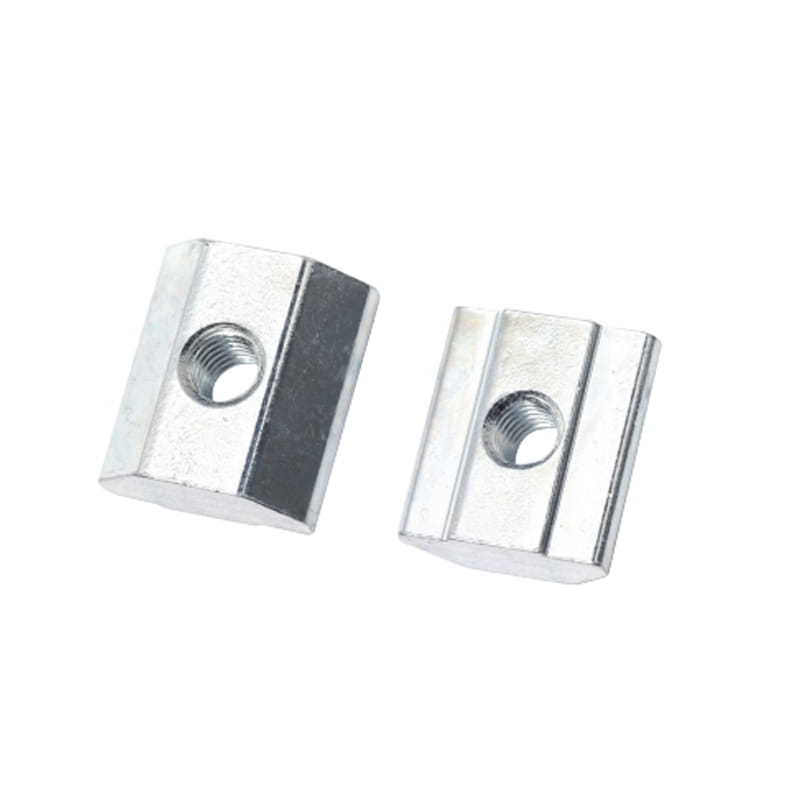

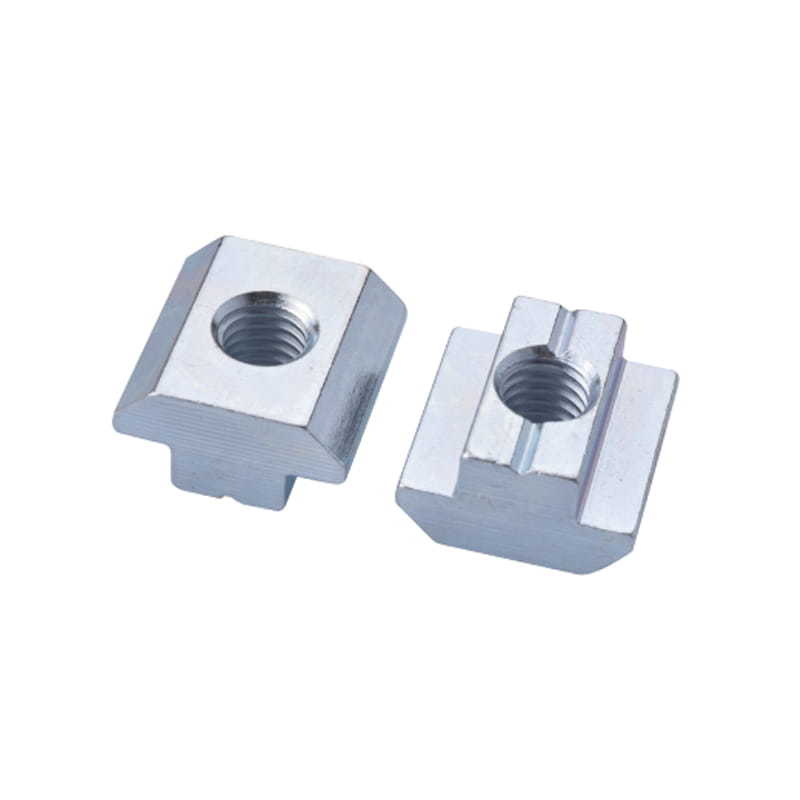

The material selection and manufacturing process of your Profile T Slide Nut / T-Slot Nut are one of the key factors that determine its quality and performance. These connectors are usually made of high-strength metal materials, such as aluminum alloy, stainless steel, etc., to ensure sufficient durability and load-bearing capacity.

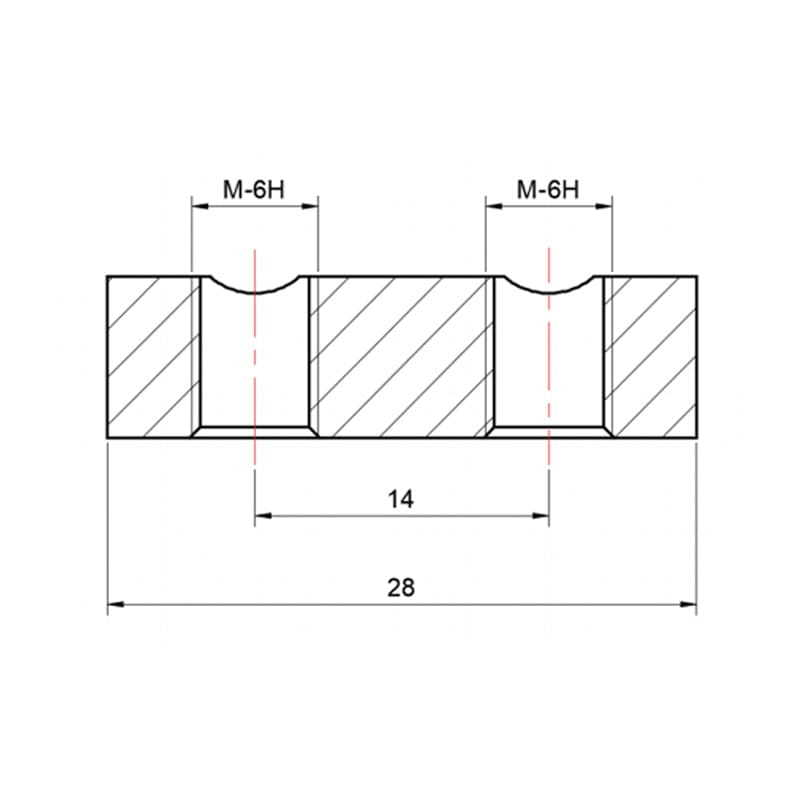

The process of manufacturing these nuts usually involves advanced machining techniques such as milling, turning, drilling, etc. to ensure their dimensional accuracy and surface quality. Its manufacturing process may also include special surface treatments, such as anodizing, spraying, etc., to improve its corrosion and wear resistance.

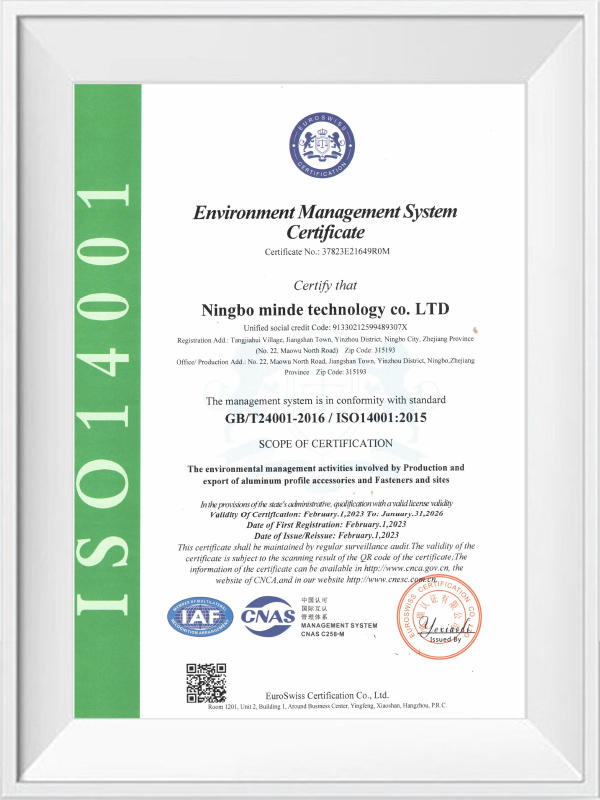

These material and manufacturing process choices make Profile T Slide Nut / T-Slot Nut ideal for a variety of harsh environments and high-load applications. They maintain stable performance over time in a variety of industrial and mechanical environments, reducing the need for maintenance and replacement, thereby lowering overall costs.

3. How is the performance and reliability of Profile T Slide Nut / T-Slot Nut guaranteed?

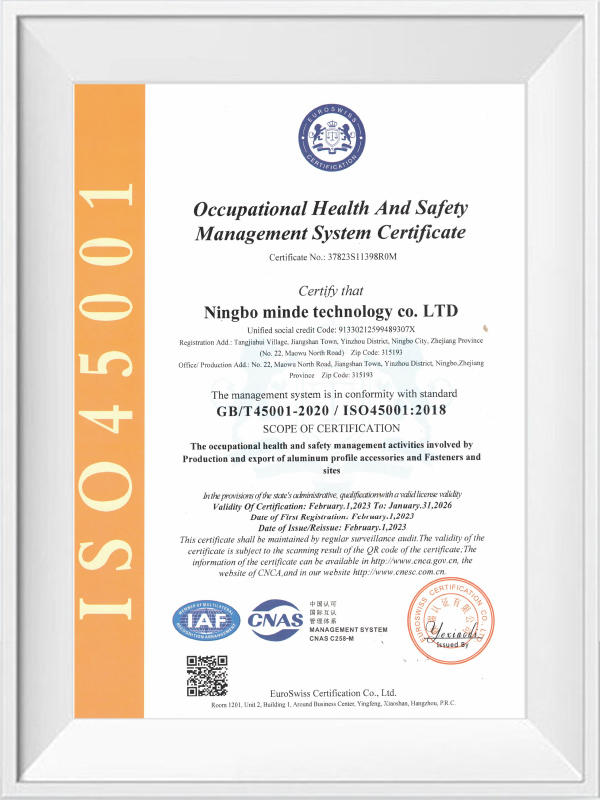

Profile T Slide Nut / T-Slot Nut plays an important role in industrial manufacturing where performance and reliability are critical. The design and manufacturing process of these connectors focuses on ensuring consistent performance and reliability.

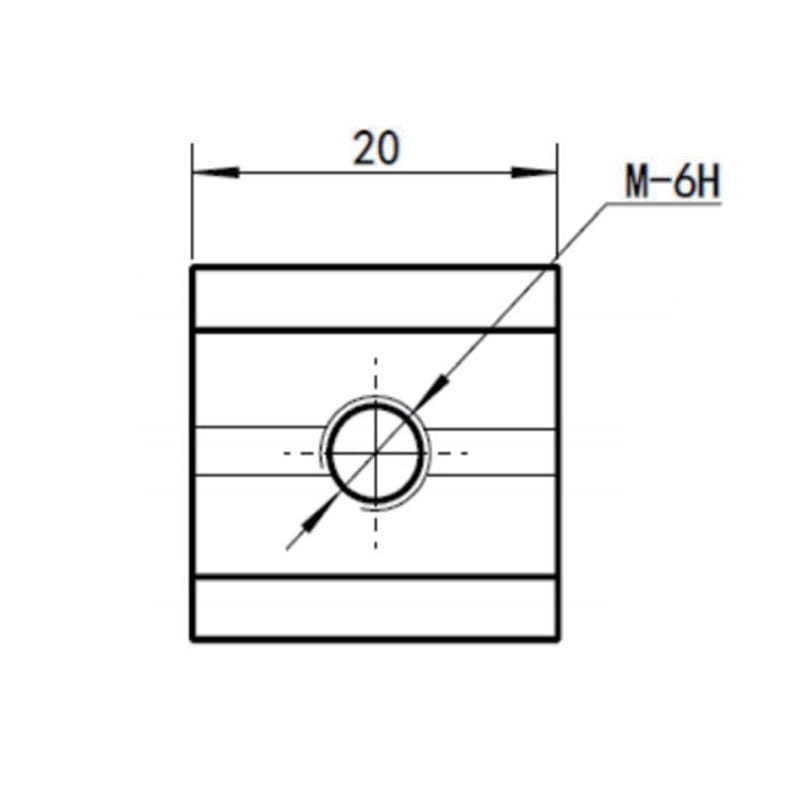

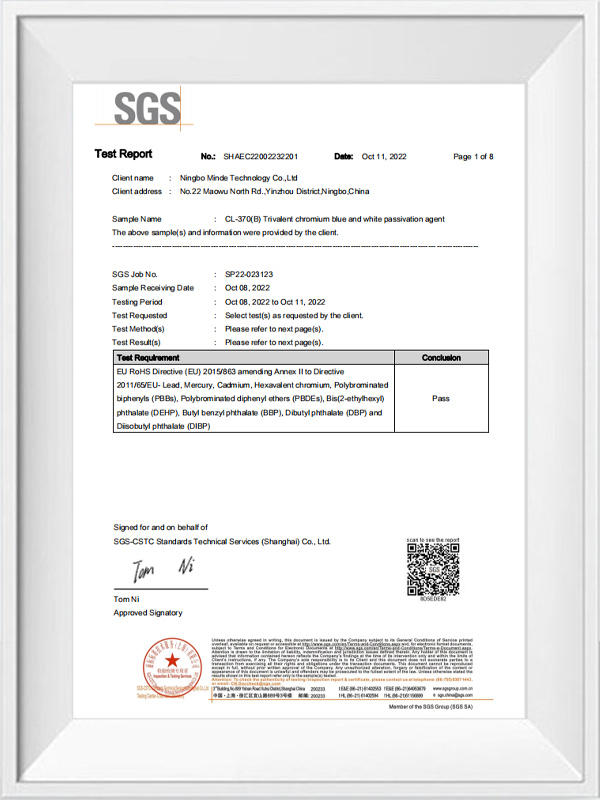

These nuts are precision engineered to ensure a perfect fit in the T-slot, providing a secure connection. Its material selection and manufacturing process are also key factors in ensuring its performance. Typically, these nuts are made of high-strength metal materials and undergo precision machining and surface treatment to ensure they have good corrosion resistance and wear resistance.

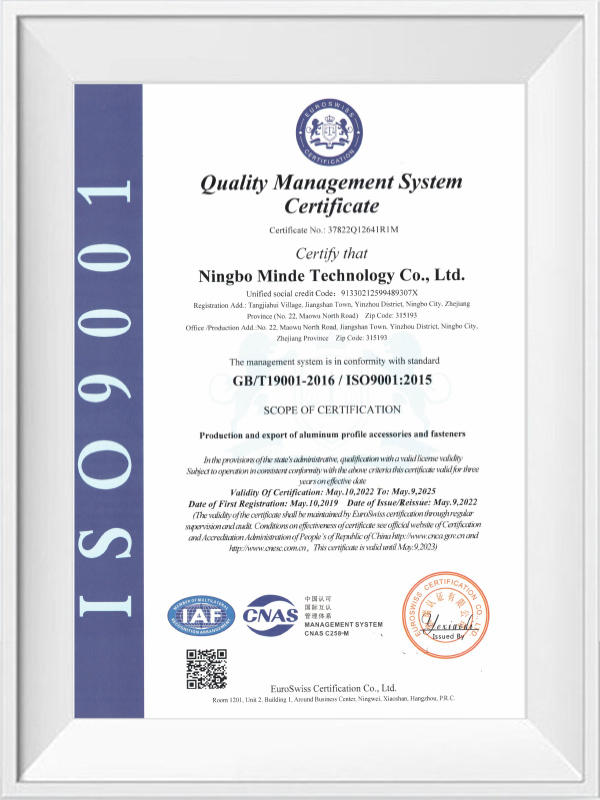

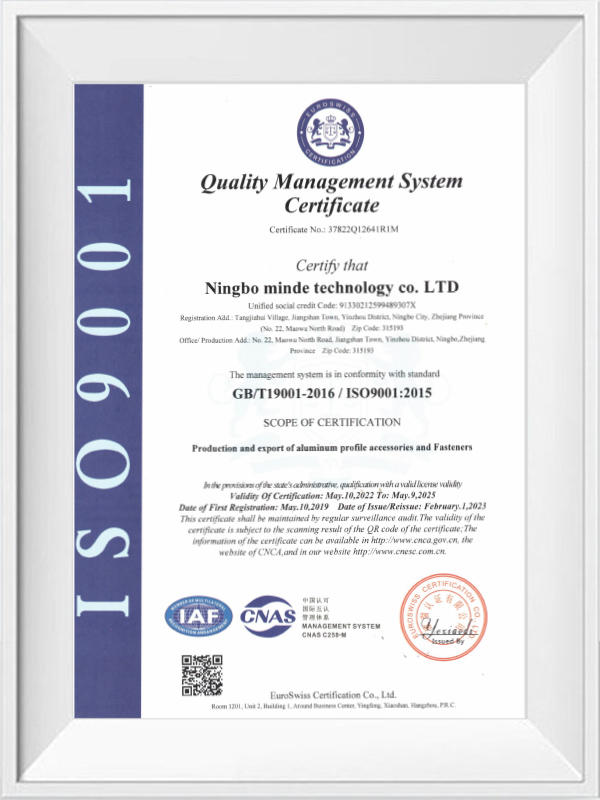

Profile T Slide Nut / T-Slot Nut undergoes strict quality control and testing to ensure that it complies with relevant standards and specifications. These tests may involve dimensional inspection, load-bearing capacity testing, durability testing, etc. to verify its performance under various working conditions.

In addition, manufacturers often provide relevant installation guides and instructions to ensure that these connections are installed and used correctly. This helps maximize its performance and extend its lifespan.