Functional application of T Slot Profile End Caps

T Slot Profile End Caps play a vital role in the industrial field, and their functions and applications cover many aspects, from improving structural integrity to enhancing safety and aesthetics.

One of the main functions of the end seal is to protect the end of the T-slot aluminum profile. This protective function prevents external environmental factors such as dust, impurities, and moisture from intruding into the interior of the structure. In industrial production environments, especially in places where equipment and structures need to be kept clean, the use of end seals can effectively prevent the accumulation of impurities and improve the reliability and durability of the overall system.

End seals play a critical role in structural integrity. By closing the ends of T-channel aluminum profiles, end seals give the structure a more compact, cleaner appearance. This is critical for applications that require structural aesthetics, reduced air resistance, or reduced vibration and noise. At the same time, the use of end seals can also reduce material loss and ensure the stability of the overall structure.

In terms of industrial safety, T-slot aluminum profile end seals can reduce the risk of accidents. By closing off the end of the profile, end seals effectively prevent people or equipment from accidentally coming into contact with sharp edges, reducing the potential risk of trauma. Especially in some environments that require frequent operations and personnel contact, end seals have become key safety accessories to provide workers with a safer working environment.

In addition, end seals can also be used as a means of structural adjustment. Some specially designed end seals allow users to easily adjust the structure, replace parts or perform maintenance work when needed. This flexibility makes T-slot aluminum profiles more suitable for various applications, while also reducing the difficulty and cost of maintenance and replacement of parts.

The choice of material and color of the end seal can add a decorative touch to the structure. By selecting end seals that fit a specific industry or company profile, you can add a personal touch to the overall system. This is especially important for industries that have brand identity requirements or focus on appearance design, which can enhance the overall aesthetics of the product or device while maintaining functionality.

Structural features of T Slot Profile End Caps

T Slot Profile End Caps, as an important component that complements T-slot aluminum profiles, have a series of carefully designed structural features to meet various needs in the industrial and manufacturing fields.

The material selection of the end seal is an important part of its structural characteristics. Commonly used materials include plastic, rubber, silicone, etc. These materials are wear-resistant, corrosion-resistant, anti-aging and can maintain stable performance in various harsh environments. In addition, these materials usually have a certain degree of elasticity and can better adapt to the end shape of the T-channel aluminum profile, ensuring that the seal can fit tightly and achieve the best sealing effect.

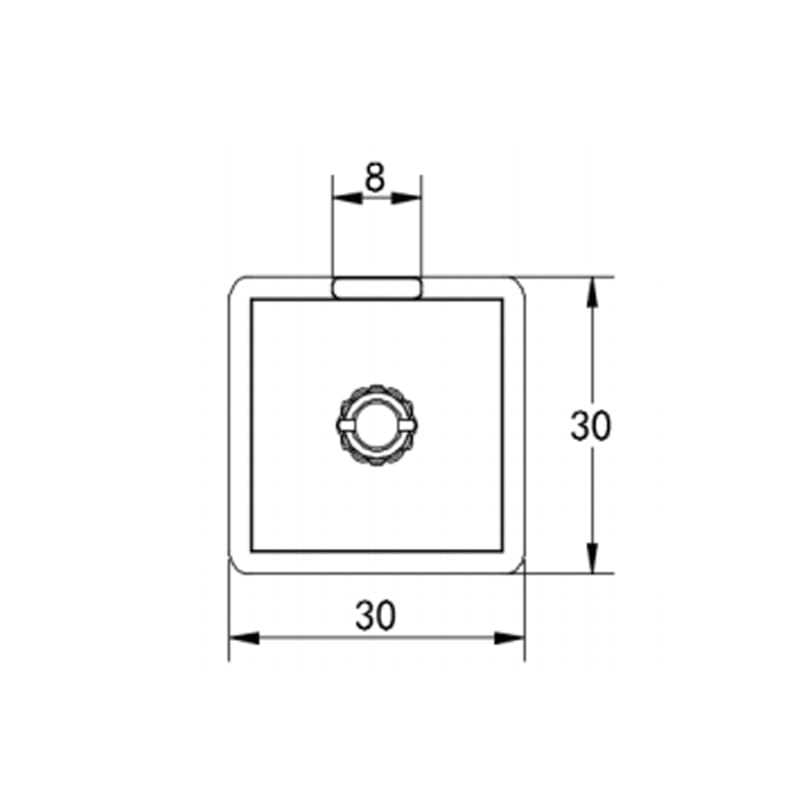

The structural design of the end seal usually takes into account the requirements for easy installation and disassembly. In order to facilitate users to replace or maintain seals when needed, their structures usually adopt simple and effective connection methods, such as mortise and tenon, buckles, etc. This design ensures that users can easily adjust and maintain the structure, improving the flexibility of the overall system.

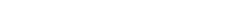

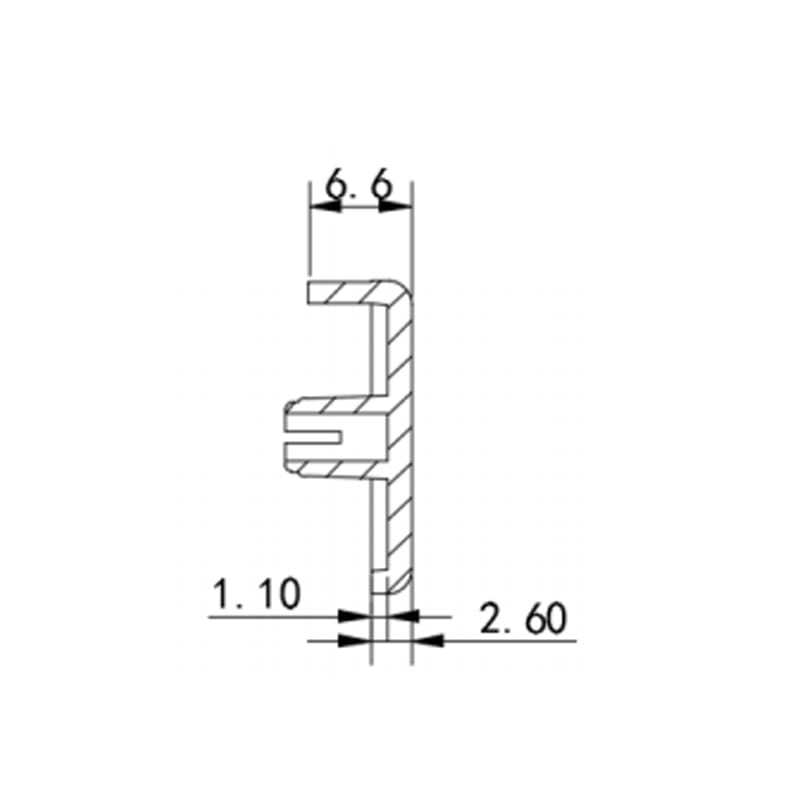

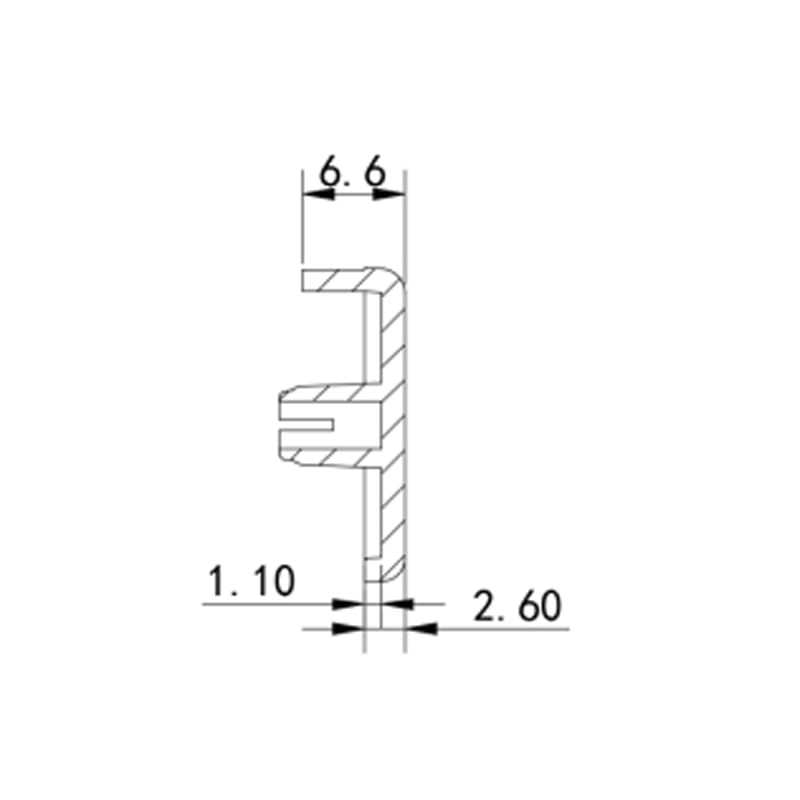

In terms of structural shape, the T-slot aluminum profile end seal is usually designed to match the T-slot aluminum profile end. This means that the shape of the seal is consistent with the end shape of the T-slot aluminum profile, ensuring that the seal can fit tightly on the T-slot aluminum profile to form an effective seal. At the same time, this matching design also helps to improve the appearance of the overall structure, making it look neater and more coordinated.

On the other hand, some T-slot aluminum profile end seals may also have adjustable features. This design allows users to adjust the position or tightening of the seal according to specific needs to adapt to different working scenarios. The adjustable structural features make these seals more flexible and can be adapted to various special engineering requirements.

In some high-demand applications, T-slot aluminum profile end seals may also have special functions such as waterproofing, dustproofing, and earthquake resistance. This requires the seal to consider more details in the structural design to ensure the best effect in a complex working environment and protect the T-slot aluminum profile and its internal structure.