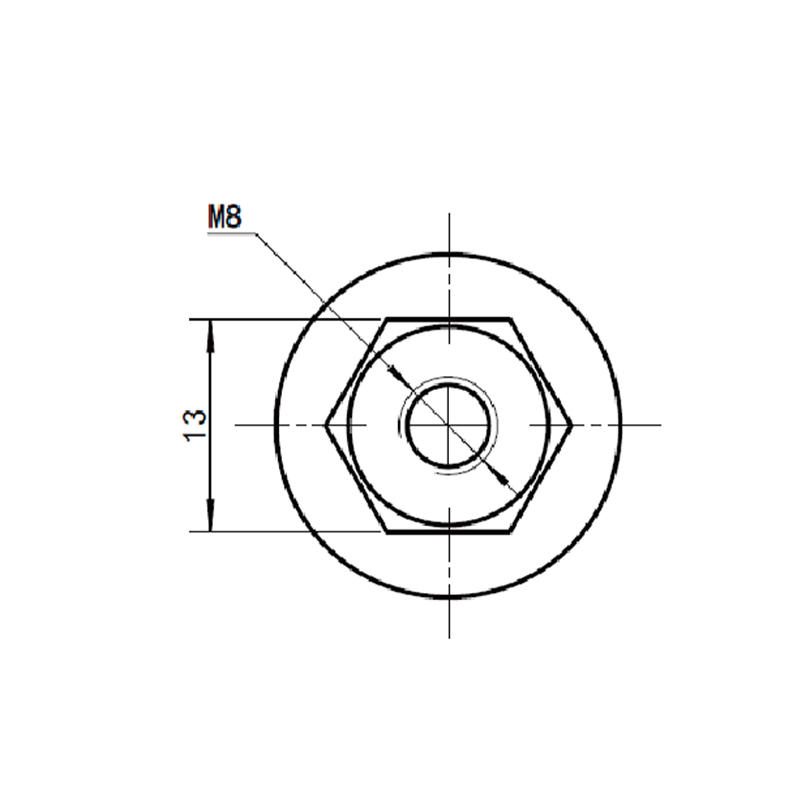

1. Design and structure of Flange Nuts

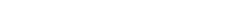

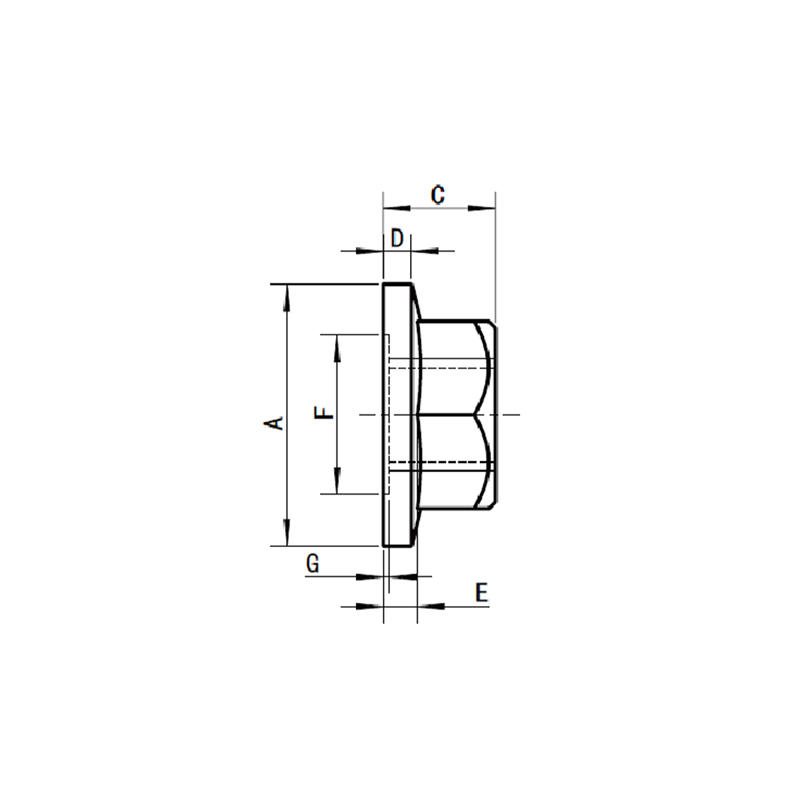

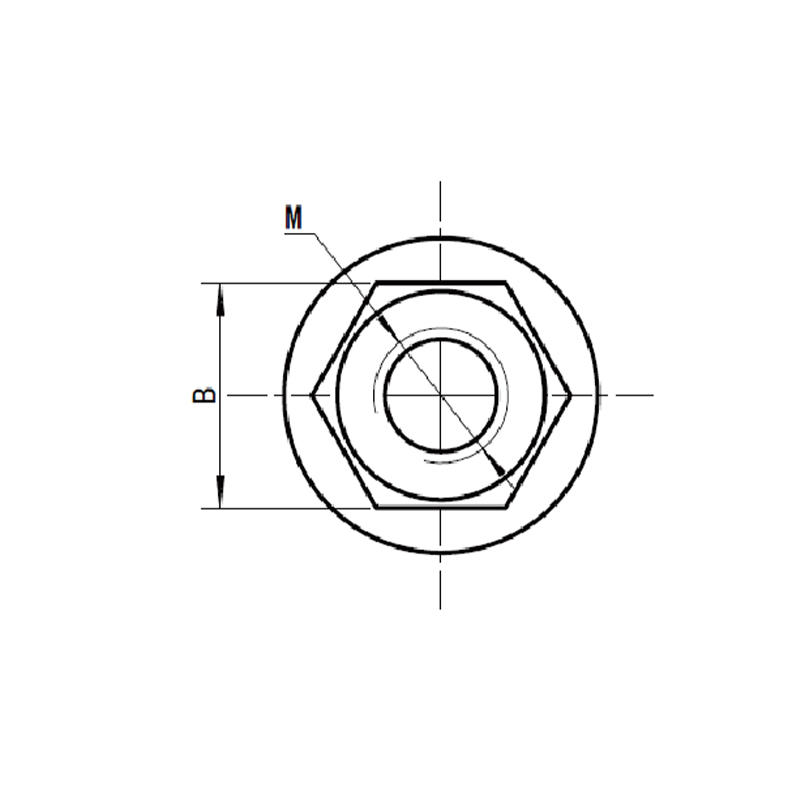

Flange nuts are designed to respond to specific engineering needs and their structure is unique compared to ordinary nuts. First, Flange Nuts add a flat flange to the nut, which is usually located at the bottom of the nut. The existence of this flange allows Flange Nuts to provide additional support and fixation when tightening, thereby enhancing the stability and reliability of the threaded connection. In some designs, the outside of the flange may have a pattern or tooth-like structure to increase its grip on the material surface and further improve the tightening effect.

The structure of Flange Nuts also includes a threaded part, which is basically the same as the threaded structure of ordinary nuts. The design of the threads follows international standards to ensure compatibility with standard bolts, threaded holes and other threaded parts. In addition, the material selection of Flange Nuts is also very important. High-strength metal materials, such as carbon steel and stainless steel, are usually used to ensure their reliability and durability in high-strength engineering environments.

For the design of Flange Nuts, various engineering conditions and usage environments need to be taken into consideration. For example, in a vibration environment, the design of the flange can effectively prevent the nut from loosening and improve the stability of the connection. In addition, the flat flange design of Flange Nuts also makes it easier to install and disassemble in limited spaces, which is especially important for certain engineering applications.

Flange Nuts are designed as an engineering innovation to provide a more reliable and stable threaded connection solution for a variety of industrial and mechanical applications.

2. Application fields and case analysis of Flange Nuts

Flange Nuts have a wide range of applications in the engineering field, and their stability and reliability make them a key component of many important mechanical systems. In the automotive industry, Flange Nuts are commonly used in automotive engines, chassis and tire assembly to ensure safety and stability at high speeds and in harsh road conditions. For example, automobile hub nuts are often designed with Flange Nuts to ensure a secure connection between the hub and the wheel while resisting road vibration and steering forces.

In the field of machinery manufacturing, Flange Nuts are widely used for the assembly and fixation of mechanical equipment, tools and facilities. For example, in the aerospace industry, aircraft structural components and cabin equipment require highly reliable connections to cope with extreme climate and flight conditions, and Flange Nuts are ideal for meeting this need.

In addition, Flange Nuts also have important applications in various fields such as construction engineering, railway transportation, and energy. Its stable connection and resistance to loosening allow it to play a key role in various engineering projects.

We can clearly see the application and value of Flange Nuts in different fields, as well as its important contribution to engineering safety and reliability.

3. Advantages and future development trends of Flange Nuts

Flange Nuts have many advantages over traditional nuts, which make them one of the preferred connectors in many engineering designs. First of all, the design of Flange Nuts can significantly improve the stability and reliability of the connection, especially in high-vibration and high-pressure environments, and its ability to resist loosening is even more prominent. This makes Flange Nuts excellent in applications requiring long-term stable operation and high load conditions.

Flange Nuts are relatively easy to install and remove, which is important for maintenance and repair work. The flange design makes it easier for the installer to secure the nut onto the bolt and is more convenient when replacement or adjustment is needed.

In the future, with the continuous development and innovation of engineering technology, Flange Nuts may usher in more improvements and optimizations. For example, through the application of new materials and improvements in manufacturing processes, the performance and durability of Flange Nuts can be further improved, making it suitable for more harsh engineering environments. In addition, with the advancement of industrial automation and digital technology, the production and application of Flange Nuts will become more intelligent and efficient, thereby further enhancing its application value in the engineering field.