1.Understanding the Basics of Profile Anchor Fasteners

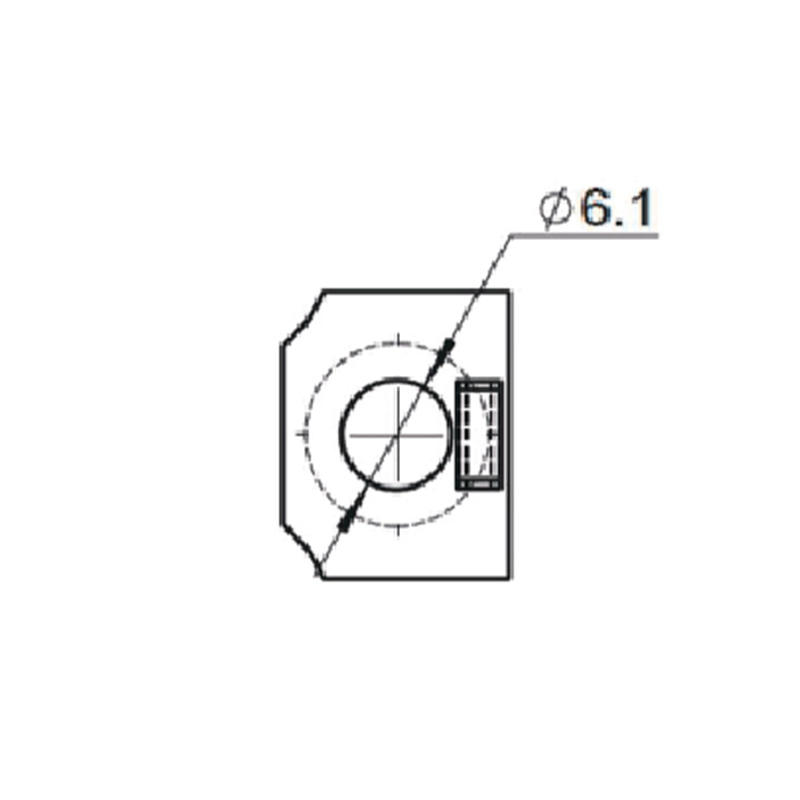

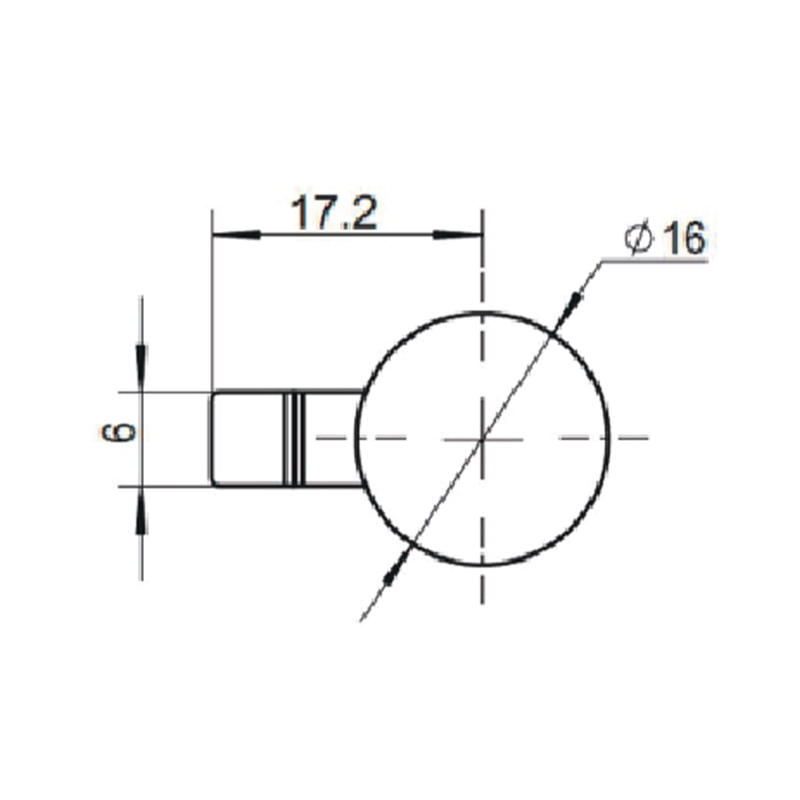

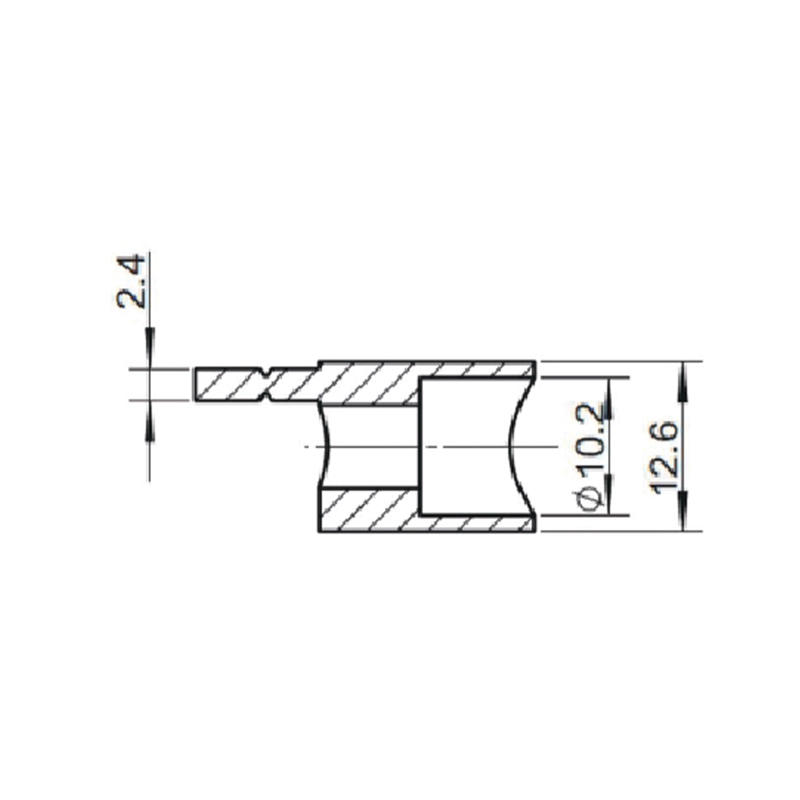

Profile anchor fasteners form the backbone of numerous construction and industrial projects, playing a pivotal role in ensuring the stability and reliability of structures. At their core, these fasteners are mechanical devices designed to secure objects or materials to a base material, such as concrete, masonry, or metal. Their versatility stems from a straightforward yet ingenious design that allows for efficient load transfer and anchoring in diverse applications. These fasteners typically consist of three primary components: the anchor body, the nut, and the washer. The anchor body, often featuring a threaded or serrated design, is responsible for gripping the base material securely. The nut, when tightened onto the anchor body, facilitates the clamping force required to affix objects to the substrate. The washer acts as a distribution plate, enhancing load distribution and mitigating the risk of damage to the substrate during installation.

2.Installation Best Practices for Profile Anchor Fasteners

The installation of profile anchor fasteners is a critical phase that demands precision and adherence to established guidelines. Proper installation not only ensures the structural integrity of the fasteners but also contributes significantly to the overall safety and stability of the construction. Here are some best practices to consider:

a)Drilling: Use the appropriate drill bit size to create clean and accurately sized holes in the substrate. Ensure that the hole depth and diameter align with the specifications provided by the fastener manufacturer. Remove any debris from the hole before inserting the anchor to guarantee optimal engagement.

b)Setting Depth: Follow the recommended setting depth to allow the anchor to achieve full embedment and optimal load-bearing capacity.

Utilize depth gauges or markings on the drill bit to ensure accurate and consistent setting depths across multiple installations.

c)Torque Values: Refer to the manufacturer's specifications for torque values during the tightening of nuts on threaded anchors. Employ torque wrenches to achieve precise torque levels, preventing over-tightening or under-tightening that could compromise the anchor's performance.

d)Inspection: Regularly inspect the installed anchors to identify any signs of displacement, corrosion, or other issues that might compromise their effectiveness. Address any deviations from the installation guidelines promptly to maintain the integrity of the anchoring system.

3.Load Capacities and Performance Characteristics

Understanding the load capacities and performance characteristics of

profile anchor fasteners is paramount to the success of any construction project. Several factors influence the overall performance of these fasteners:

a)Substrate Type: Different base materials exhibit varying load-bearing capacities. Understand the characteristics of the substrate (e.g., concrete, masonry, or metal) to select the appropriate anchor type and size.

b)Embedment Depth: The depth at which the anchor is set within the substrate directly impacts its load-bearing capacity. Follow manufacturer guidelines to determine the optimal embedment depth based on the specific application.

c)Anchor Spacing: Proper spacing between anchors is crucial for even load distribution. Consider the recommended anchor spacing to avoid overloading individual fasteners and to ensure the uniform transfer of loads.