The transition from the conventional stamping process to the advanced Cold Forging Technology for T nut production marks a significant leap in manufacturing efficiency. Cold forging involves shaping metal at ambient temperatures, optimizing material strength, and minimizing waste. This innovative method utilizes high-pressure compressive forces to form T nuts, enhancing their mechanical properties and overall durability. The switch to cold forging represents a strategic advancement, streamlining production processes and ensuring precise control over product dimensions. This technology not only elevates efficiency but also contributes to sustainability by reducing material scrap. The Cold Forging process for T nuts exemplifies a commitment to progressive manufacturing, aligning with industry demands for high-performance components. This strategic shift underscores dedication to quality improvement, positioning the production line at the forefront of precision engineering and modern manufacturing practices.

Ningbo Minde Technology Co., Ltd.

- Products

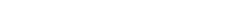

- Profile Fastening Accessories

- Profile Connecting Systems

- Alu. Angle Connectors / Alu. Corner Brackets

- Zinc Casting Gussets / Zinc Casting Corner Brackets

- Steel Angle Connectors / Steel Corner Brackets

- Inside Corner Brackets / Al. Connection Angles

- Profile 3-way Cubic Connectors

- 2 Profile ways Cubic Connectors

- 3-way Connection Angles / 3D Corner Brackets

- Profile Bolt Connectors

- Profile Central Connectors / Quick Connectors

- Profile Connection Plates

- Profile Automatic Connectors

- Profile Central Screws / Profile Central Bolts

- Profile Plate Connectors

- Profile Anchor Fasteners

- T Slot Profile Inner Connector

- Profile End Fasteners

- Profile Pivot Joints

- Profile Connector 90°

- 3-Way End Corner Connector

- Profile Turning Plates

- Profile slide hooks

- Profile Panels & Doors Fasteners

- T Slot Floor Elements

- T Slot Covers

- T Slot Profile End Caps

- Cable Tie Mounting Blocks

- Solar Mounting Components

- Customized Machinery Components

- Profile Sliders & Rollers

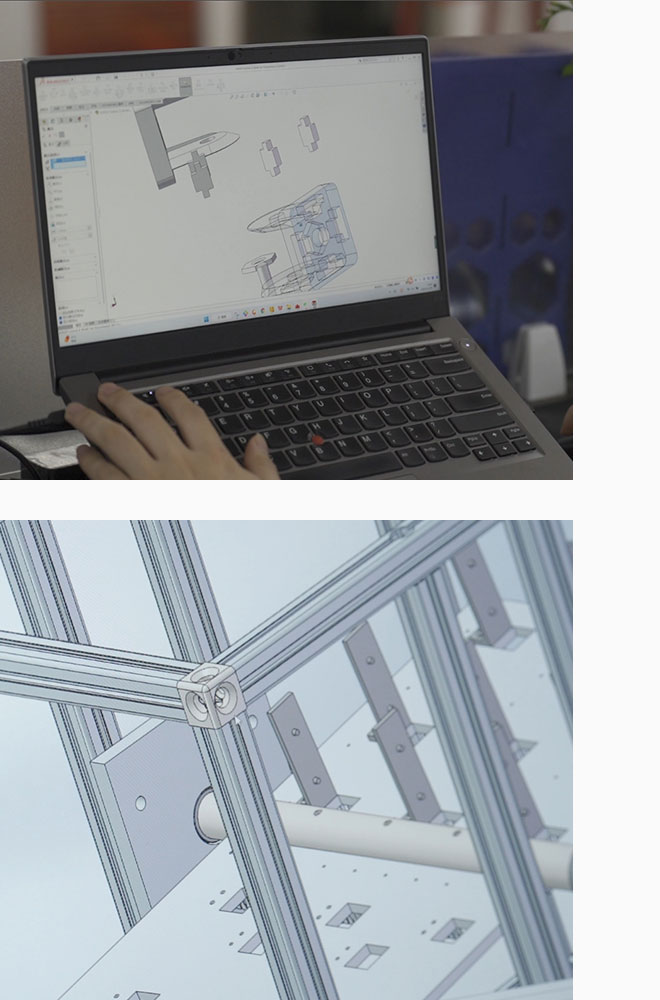

- Technology

- Applications

- News

- Company

- Contact